Der Beitrag Why EDI Transformation is Critical to the Success of Your Organisation erschien zuerst auf ecosio.

]]>- An EDI transformation project typically includes analysis of the current infrastructure, target definition, modernisation of existing EDI architecture, and implementation of new components

- Benefits include increased efficiency, improved data quality, more time for value-adding tasks, greater flexibility, easier partner integration, and future-proof systems

- Challenges include high investments, technical complexity, and resistance to change

- Tips for success are don’t underestimate internal effort, take future requirements into account, and don’t put the project off

Nowadays it’s no longer enough just to optimise processes – companies need to fundamentally rethink their approach to data communication in order to maintain their position in the market. To secure fast, automated and error-free communication with business partners, many businesses today are embarking on ambitious EDI transformation projects. But what exactly does an EDI transformation project involve, and how exactly can a successful project benefit your company?

What does an EDI transformation project involve?

An EDI transformation project typically consists of the following key steps:

- Analysis of the current infrastructure: evaluation of existing systems to identify weaknesses and opportunities for optimisation

- Target definition: Definition of requirements and targets, e.g. higher data quality or cost reductions

- System migration: Conversion to a more modern, often cloud-based, EDI solution

- Integration: Connection of new EDI solution to existing ERP system to ensure seamless communication

- Change management: Comprehensive training and clear process communication to make the transition easier for employees

Why is EDI transformation crucial for companies?

Companies that neglect to modernise their EDI systems run the risk of being left behind. Outdated systems can slow down data exchange, affect data quality and create security gaps. In order to remain competitive, companies must integrate modern technology in the form of cloud solutions, APIs and automated processes.

For those companies that do this successfully, the advantages are numerous, including…

- Increased efficiency: the automation and optimisation of processes reduces manual intervention and speeds up workflows

- Improved data quality: Modern EDI systems ensure accurate, error-free data transmission

- More time to focus on value-adding tasks: Automated processes ensure employees have more time for strategic activities

- Increased flexibility and scalability: With more streamlined EDI processes and better data visibility, companies can react quickly to market changes and adapt their processes accordingly

- Easier integration of new partners: A modern EDI infrastructure simplifies the integration of business partners and increases collaboration

- Future-proof systems and processes: With a continuously customisable EDI solution, companies remain competitive in the long term

What challenges do EDI transformation projects pose?

As with all large IT projects, success isn’t guaranteed, and there are generally hurdles along the way. When it comes to EDI transformation projects, the most common issues companies experience include…

High investments

Although not always the case, EDI transformation projects often require significant upfront investment. The costs can include new software and infrastructure, integration work, consultancy fees, and the time and personnel needed to manage change across systems and processes. For many organisations, this initial outlay can seem daunting, especially when existing systems are still operational, albeit inefficient. However, while the short-term costs are substantial, these investments are typically offset over time through improved operational efficiency, automation of manual tasks, fewer errors, and reduced long-term operating expenses. In this way, a well-executed EDI transformation not only pays for itself but also creates measurable value for the business.

Technical complexity

Integrating modern systems into existing IT infrastructures can be a challenge, especially if the old software has been heavily customised. This often requires complex customisations to make new technologies compatible with the old systems. These customisations require in-depth technical knowledge and careful planning to ensure a smooth integration. It’s important that the new systems work efficiently with the existing infrastructure without interrupting business processes. A strategic approach is therefore crucial for the long-term success of the integration.

Resistance to change

Employees who are used to old ways of working may resist the new technologies. However, thorough training and clear communication will help overcome this resistance.

Overcoming these challenges requires careful planning and expert support.

Three important tips for a successful EDI transformation project

- Don’t underestimate the internal effort: a successful transformation requires co-operation and the right resources in the team. Ensure that everyone involved is adequately trained and supported.

- Take future requirements into account: Choose an EDI solution that will grow with your business and can adapt when your needs change.

- Don’t put the project off: Start your EDI transformation as early as possible to avoid missing an opportunity to increase efficiency and gain a competitive advantage. By delaying, your existing solution will only become even more

Let us help you achieve EDI transformation success!

EDI transformation is not only a technical necessity, but also a strategic step to secure your long-term competitiveness. With ecosio, you can modernise your EDI processes and successfully meet the challenges of the digital future. Are you ready to take your EDI systems to the next level? Contact us to find out how you can become more efficient, flexible and future-proof with ecosio’s unique ED-as a Service approach.

We’re always happy to help!

Der Beitrag Why EDI Transformation is Critical to the Success of Your Organisation erschien zuerst auf ecosio.

]]>Der Beitrag Can Increased Automation Build Supply Chain Resilience? erschien zuerst auf ecosio.

]]>- The last five years has seen a surge in recognition by businesses of the importance of building supply chain resilience

- Automating key B2B processes minimises the potential for human error, improves speed, and frees up staff to focus on more valuable tasks

- In a survey of supply chain executives, 88% believe that optimising automated B2B processes can improve supply chain resilience, and over half predicted that efficient automation would improve it “substantially

- 62% of respondents saw automated B2B communication as “very important” to the success of their business moving forward, with none seeing it as unimportant or irrelevant

The last five years has seen a surge in recognition by businesses of the importance of building supply chain resilience. Global events have highlighted the dangers of being unable to react to disruptions, and organisations are increasingly aware of the value of flexibility and adaptability, particularly when it comes to critical B2B processes. Yet despite this, according to a recent KPMG survey, 47% of supply chain executives believe they are still “vulnerable to disruption”.

While there is obviously no way to predict the future, there are pragmatic steps that businesses can take to boost supply chain resilience. Perhaps the simplest and fastest of these to achieve is improving B2B automation. Not only does automating key processes minimise the potential for human error, it can also improve speed and free up staff members to focus on more valuable tasks. In the event of unforeseen circumstances, businesses thus benefit from increased flexibility, as the majority of business-critical tasks aren’t dependent on human intervention.

What our research shows

As part of a wider research project concerning B2B integration trends, we recently conducted our own cross-industry survey in which we asked people their views on the importance of B2B automation.

Of the over 100 supply chain executives we surveyed, 88% believe that optimising automated B2B processes can improve supply chain resilience. Further, over half of those surveyed predicted that efficient automation would improve supply chain resilience “substantially”.

Similarly, 62% of respondents saw automated B2B communication as “very important” to the success of their business moving forward, with none seeing it as unimportant or irrelevant.

What can you do?

Improve and expand automation of business-critical processes! Not only will expanding and optimising automated processes streamline processes and minimise the possibility of human errors, it will also free up internal teams to be able to focus on more value-adding activities.

In particular, introducing electronic data interchange (EDI) and e-invoicing can make a huge difference to the efficiency of day-to-day messaging and drastically improve supply chain resilience.

“As more of the supply chain becomes automated, roles can be redefined to focus on higher-value customer services, and new roles will emerge for humans that drive strategy and innovation.”

Questions to ask yourself

- Are existing B2B integration processes inhibiting your company’s ability to react quickly to market changes?

- Do you currently have business-critical processes that could be automated?

- Are any key supply chain operations reliant on one or two individuals?

- Have you considered investing in a Web EDI solution to extend automation across your entire partner landscape?

- Would internal team members be able to add more value elsewhere if EDI tasks were outsourced?

Want more information on EDI trends?

This article is based on a chapter from our white paper “The Future of B2B Integration – Market Trends Report”, in which we share survey results as well as predictions concerning the evolution of B2B integration. To download your free copy now, simply visit the white paper page and enter your details!

Discover more about our updated product, ecosio.flow.

Der Beitrag Can Increased Automation Build Supply Chain Resilience? erschien zuerst auf ecosio.

]]>Der Beitrag EDI Integration with Infor M3 erschien zuerst auf ecosio.

]]>- Infor M3 is a flexible ERP solution that can be operated both in the cloud and locally, popular with large and mid-sized companies managing complex supply chains

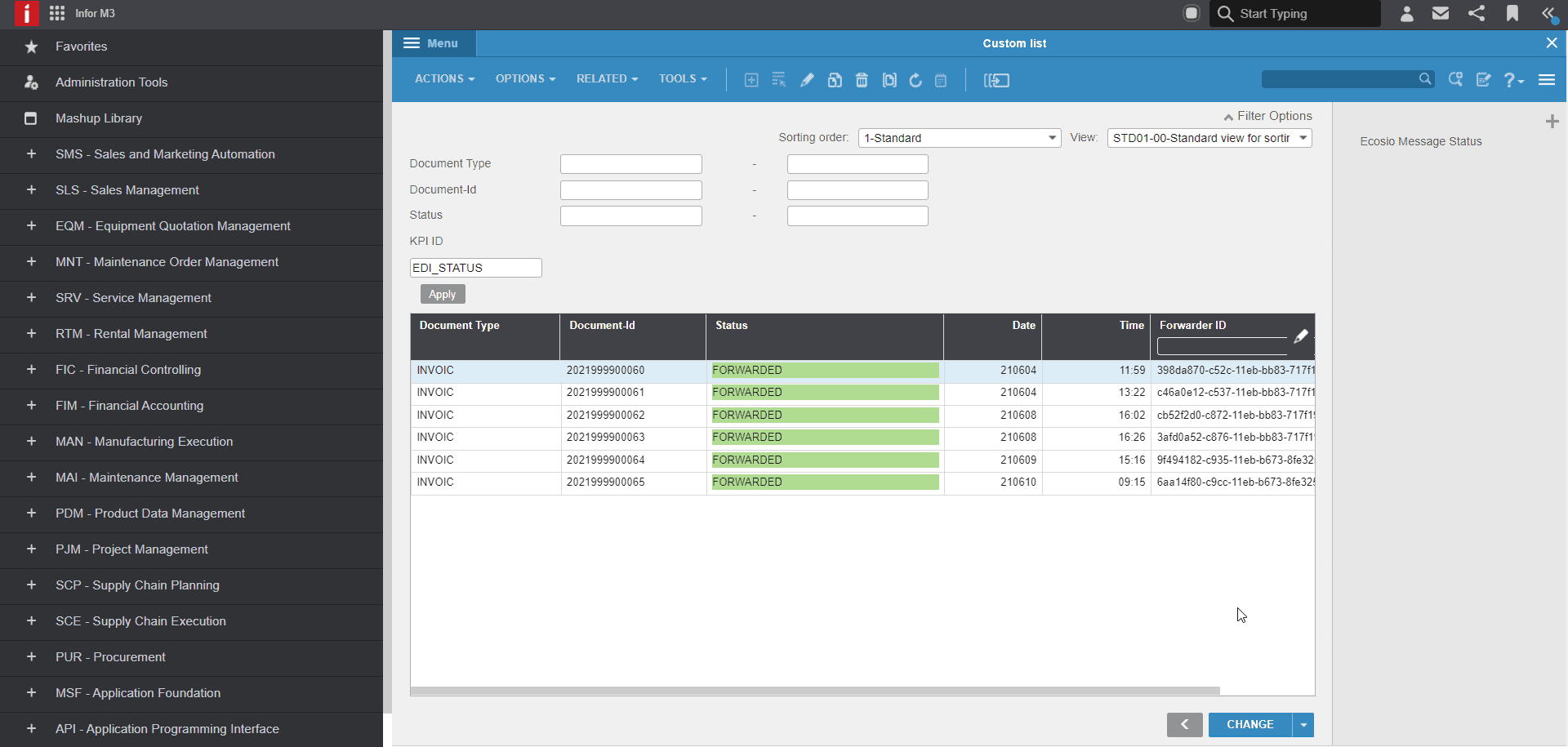

- Deep EDI integration is achieved via an API connection, allowing real-time message status tracking and full data transparency directly within the Infor M3 interface

- ecosio’s fully managed EDI service offers proactive monitoring, partner onboarding, and 24/7 support, eliminating the need for in-house EDI expertise

- ecosio’s cloud-based EDI solution ensures scalability, supporting current and future EDI and e-invoicing requirements

Today, more and more suppliers and customers are demanding a connection via EDI (electronic data interchange). If the chosen EDI solution is not deeply integrated into Infor M3, many of the advantages of such a connection are lost, however. In this article we explore what the advantages of a strong EDI connection are and how you can achieve deep EDI integration in Infor M3.

Infor M3 and EDI – stronger together

Infor M3 is a particularly flexible ERP solution that can be operated both in the cloud and locally. Thanks to its capacity to help users manage the requirements of complex supply chains, Infor M3 is particularly popular with large and mid-sized companies. For such companies, EDI – i.e. the automation of previously time-consuming and error-prone manual message exchange processes – is a key consideration.

However, in many companies EDI and ERP exist side by side rather than as a homogeneous whole. When a local EDI converter is used instead of a fully managed, cloud-based EDI solution, some essential advantages are lost, including:

- Full end-to-end message transparency from sender to recipient.

- Relief of internal teams, self service functionality for specialised teams, and the elimination of any need for internal EDI know-how.

- Support of national e-invoice requirements across various countries (Italy, Hungary, Spain, etc.).

- EDI solution flexibility/scalability.

- Round-the-clock monitoring of data exchange and proactive troubleshooting by a specialised service provider.

The key to experiencing these benefits lies in deep integration of an EDI solution in Infor M3. But what is the best way to achieve such integration? Together with our Infor partner BE-terna, we have designed a particularly flexible and future-proof solution for this…

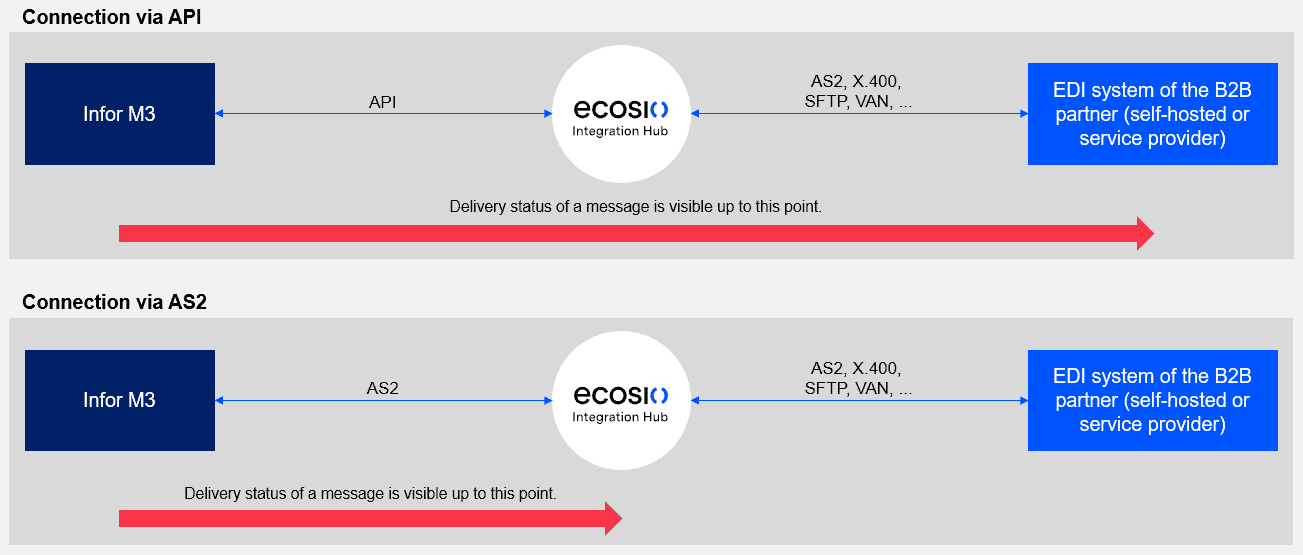

API as the game-changer

The best method to achieve seamless EDI integration in Infor M3 is via an API connection. API connections are characterised by the fact that access to data between your ERP and EDI service provider (e.g. ecosio) takes place directly via an integrated interface (i.e. the API) of the EDI service provider. This makes the B2B platform with the associated B2B network of the EDI service provider and the ERP solution a homogeneous whole. This in turn means, among other things, that the status of each message can be queried automatically and viewed in real time in your existing ERP system user interface. The potential for errors along the B2B message exchange is thus drastically reduced.

EDI via API offers true end-to-end data transparency, making it extremely easy for users to identify and resolve any errors that occur. For example, suppose you are waiting for a response from a supplier regarding an order you sent… With EDI via API, you can immediately see directly in your ERP system if an order was not received from the supplier due to an error. Such visibility is not possible via an alternative connection, e.g. via SFTP.

The use of EDI via API also offers the possibility of a full text search in Infor M3. This makes it much easier and faster to find documents when needed, as ecosio indexes all the content of a message as well as any associated metadata, such as AS2 message IDs, SFTP file name, etc. Furthermore, the newly updated ecosio Monitor (accessible via the familiar interface of Infor M3) allows users to track the history of any message.

As the data exchange takes place via ecosio’s fully managed platform, all message traffic is continuously monitored. If there is a problem with a delivery, ecosio takes over the proactive troubleshooting and will carry out any required subsequent action, e.g. a new message dispatch. In the event that you need to intervene – for example, because something is missing from the message content – you will be proactively notified. No message is left stranded, meaning you can rest assured your message exchange is running smoothly and without errors.

An API connection makes EDI in Infor M3 more transparent, easier and, of course, more cost-efficient.

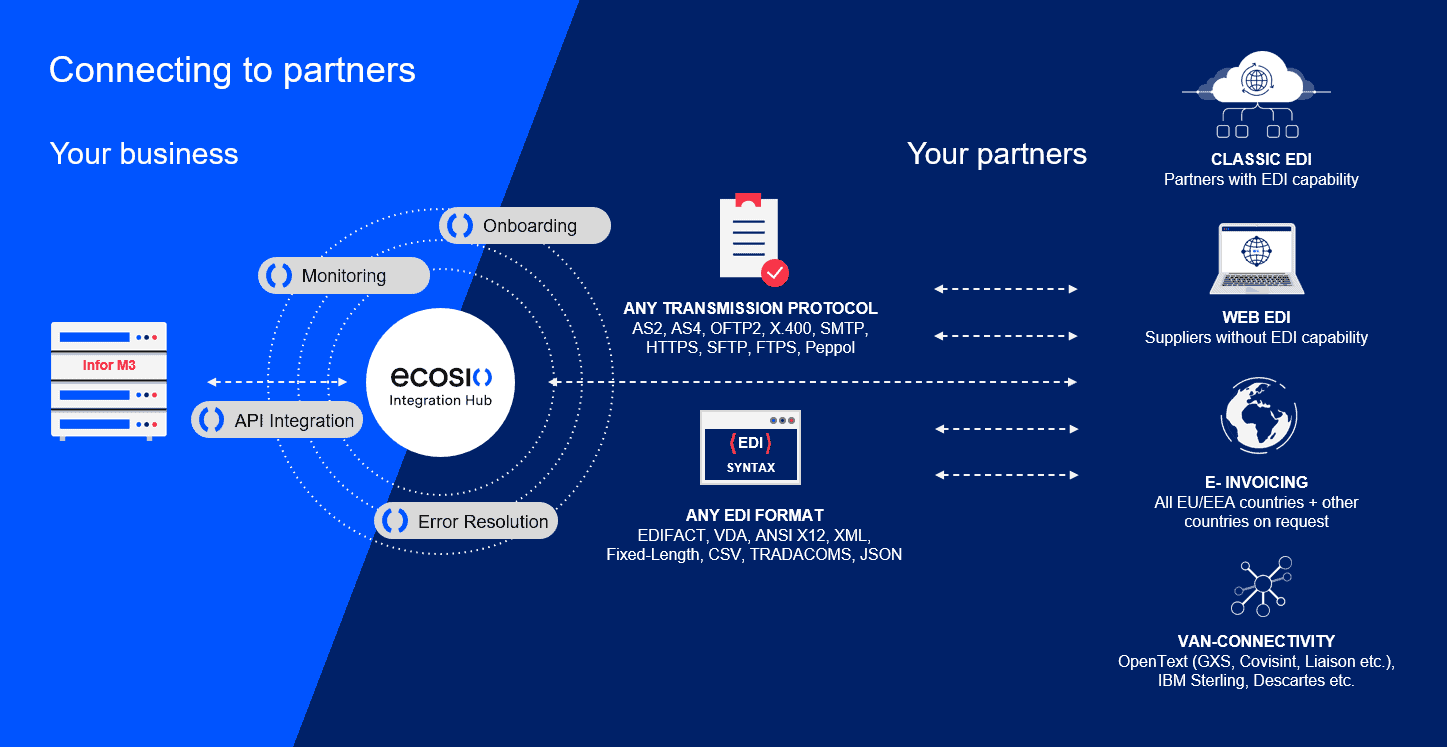

What do I have to do to achieve full EDI integration?

Not much – that’s the best part! The best fully managed EDI service providers (such as ecosio) offer API integration of all EDI functions (as well as Web EDI and e-invoicing) as a complete package. With ecosio, all this is delivered via just a single connection to the ecosio cloud-based EDI solution (our Integration Hub). This means that in addition to the benefits of seamless EDI integration in Infor M3, you also have the following advantages:

- ecosio takes over all EDI tasks, relieving internal teams and eliminating the need for in-house EDI expertise.

- The connection to the ecosio cloud-based EDI solution (our Integration Hub) enables the fulfilment of all current and future EDI or e-invoicing requirements in a flexible and scalable way.

- Dedicated ecosio Integration Engineers take care of all partner onboarding, monitor messages 24/7, and are always available as a clear point of contact for you.

- Future-proof EDI – the ecosio cloud-based EDI solution (our Integration Hub) is constantly updated and is thus always at the cutting edge of technology. ecosio’s multiple redundant server infrastructure enables updates to be installed during operation without affecting the uptime.

The project implementation and EDI integration in Infor M3 is handled completely by ecosio – together with BE-terna as Infor M3 Customiser.

Still have questions about EDI, EDI integration and Infor M3?

ecosio is an exert when it comes to seamless integration of EDI and e-invoicing in ERP systems like Infor M3. If you are interested learning more about our unique EDI as a Service solution or have further questions, please contact us without obligation – we look forward to enabling you and your company to realise the full EDI potential in Infor M3!

Discover more about our updated product, ecosio.flow.

Der Beitrag EDI Integration with Infor M3 erschien zuerst auf ecosio.

]]>Der Beitrag What is Electronic Data Interchange and What Are Its Benefits? erschien zuerst auf ecosio.

]]>- EDI enables the exchange of structured electronic business documents (orders, invoices, delivery notes, master and sector-specific data) between IT systems with zero human intervention

- EDI eliminates manual steps like printing, mailing, PDF emailing and keying in data by transmitting information directly between systems in standardised formats

- Common EDI standards include UN/EDIFACT, ANSI ASC X12, XML, CSV, and TRADACOMS, ensuring both sender and recipient interpret messages correctly

- EDI accelerates supply chain operations and just-in-time systems, while formerly used mainly by large businesses, cloud EDI now makes automation accessible to companies of all sizes

What is electronic data interchange?

The term electronic data interchange (EDI) refers to the exchange of structured electronic business documents between different business partners. EDI is not a specific technology, but an interaction of electronic processes, exchange protocols and business document standards with ultimately one central goal:

“Automated communication of information, in the form of business documents directly between two IT systems, without human intervention”.

This seamless and direct communication enables a high process automation, as business information can be exchanged between different systems quickly and without the need for PDFs/paper. Direct means that no change of the information-carrying medium is necessary during the exchange (such as the manual typing of a paper bill). The data is transferred directly from one system to the other without anyone having to intervene manually.

What is being exchanged between systems in the context of electronic data interchange? Depending on the application, this can be electronic orders, delivery notes and invoices, but also master data or sector- or industry-specific data such as transfers, delivery schedules, time lists, personal data, etc.

The steps involved in a typical exchange

Sending a paper invoice involves several steps on both the supplier’s and the receiver’s side. For the supplier the invoice needs to be generated, printed and posted. The supplier then has to wait for the document to reach their partner.

On the receiver’s side, they must first wait for the invoice to arrive. Following this, the necessary data must be manually entered into their accounting system.

In addition to being a costly and time-consuming method, the manual effort involved in exchanging paper documents can lead to errors and inconsistencies in data – a problem that can quickly escalate in fast-moving modern supply chains.

Avoiding manual effort

To avoid some of the issues with exchanging paper documents, many businesses exchange information digitally via email in the form of PDFs, word processing documents and spreadsheets. However, while this is marginally more efficient than sending physical documentation, the same key issues remain. The sender may still need to send the document manually and the receiver is still required to extract and log the relevant data themselves, all of which requires time and effort.

With EDI, the issue of manual data entry and message sending and receiving is removed completely, leading to far more streamlined supply chains.

EDI languages

With an EDI solution, relevant data is translated into a simple computer-readable language and sent directly to your partner’s system, which automatically extracts the data and stores it in the relevant place.

These EDI “languages” are text files, which condense all the necessary information into as simple and small a message as possible. To guarantee that both sender and receiver understand what is being sent and received, the content of these EDI files follows strict rules. These rules are defined in EDI standards. The two most common EDI standards are UN/EDIFACT and ANSI ASC X12, which are both delimiter-based standards. Many EDI messages are also exchanged using XML. Other widely used formats and standards also include CSV files and TRADACOMS documents (which are particularly popular in the UK).

How does EDI streamline supply chains?

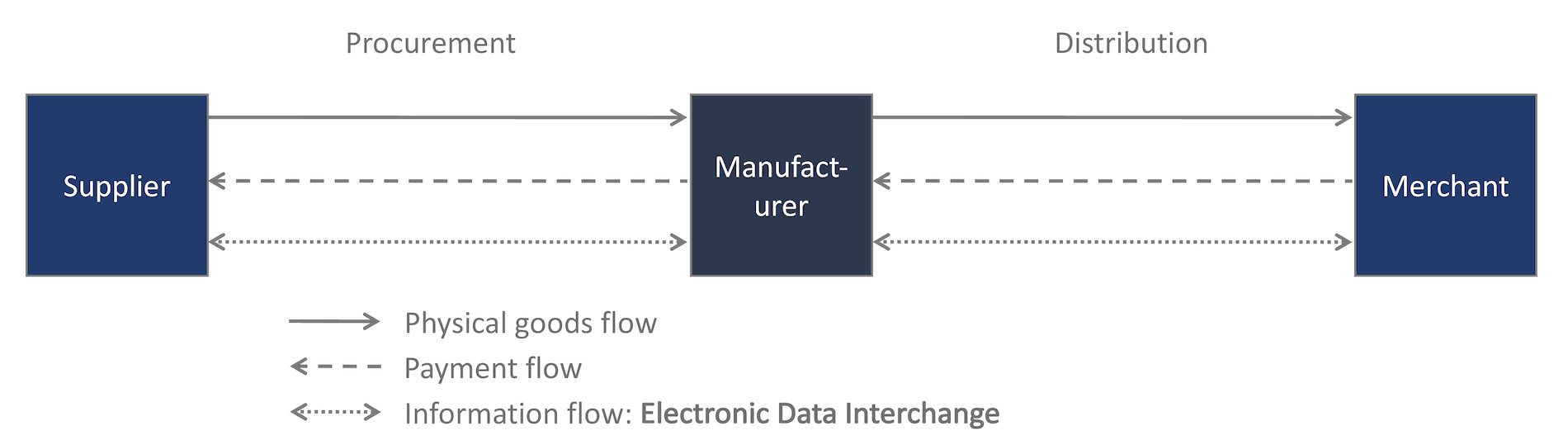

Particularly in the area of supply chain management, the use of EDI plays a very important role. The following figure shows a simplified representation of a typical supply chain scenario. For a supply chain, one thinks primarily of the flow of goods and payments. However, it is only the flow of information that makes the supply chain possible in the first place.

This flow of information was dominated by classical supply chains of paper and telephone. Later, new media such as fax or email were added.

When it came to the quantity to be ordered, the experience of the partners involved played a role – as in a classic convenience store in the 1950s.

The owners knew approximately about the expected sales and tried to manage the restocking accordingly. But, it often it came to misjudgements – then the product was simply not available, and the consumer had to wait until the goods were available again. This is an unthinkable scenario for today’s modern commerce.

The requirements for supply chains increased continuously in the industrial sector as well. Today’s supply chains have reached such high complexity and speed that the use of manual and unstructured information exchange is no longer possible.

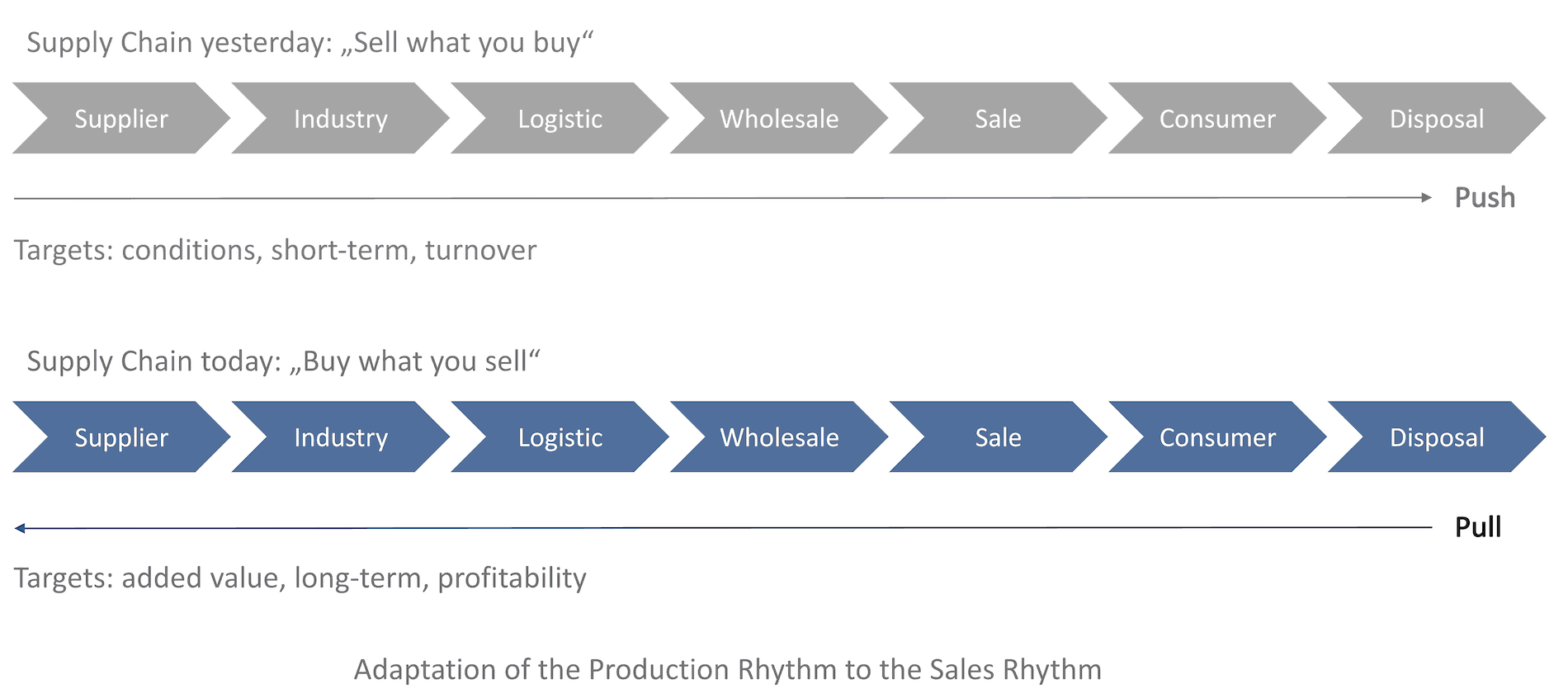

Earlier supply chains were characterised by the motto “sell what you buy”. Producing companies bought production resources, produced products and passed them on to buyers. These processes were characterised by a “push” because the sub-suppliers pushed products to the buyers. If they did not need it, the subcontractors were stuck with their stocks. Conversely, there was also the case that the demand of the buyers could not be satisfied by the offer of the producers, because too little was produced.

Supply Chains Yesterday and Today

Modern supply chains are characterized by a very close integration of the participating partners, in which customers communicate detailed forecasts of the anticipated demand for the pre-suppliers. The core motto is therefore “buy what you sell”. Products are no longer “pushed” by the producers, but “pulled” by the customers. Producers can plan production accordingly and avoid inventories which are too large or incorrect deliveries due to missing stocks.

Modern supply chains, such as those found in trade or in the automotive industry (especially just-in-time and just-in-sequence), would not be possible without the use of electronic data interchange.

What are the benefits of electronic data interchange?

As we explore in our infographic, EDI offers many significant benefits. In particular, the automation of business processes through EDI brings an extensive list of benefits in daily operations. For example:

- Faster transmission times

- Lower transmission costs

- Reduction of repeated input

- Reduction of data entry errors

- Increase the accuracy of the information

- Reduction of the paper-based document flow

- Cost savings in data handling activities

- Increasing the processing speed

- Reduction of storage costs (e.g. just-in-time or just-in-sequence)

- Avoid duplication

- Reduction of running times

- Time reduced operations

Further, EDI can also allow businesses to benefit in many other ways by ensuring that business-relevant information is available more quickly and, above all, in a structured way. The evaluation of this data by appropriate business intelligence methods enables an improved process control by data which is constantly available and up-to-date.

The impact of data visibility

In addition to providing benefits relating to automation and decision-making, the best EDI systems will be able to offer greatly improved data visibility. With such a system, users may be able to access helpful information such as whether or not their partners have received or acknowledged a certain message in real time. Similarly, real-time data visibility ensures that amendments and adjustments to key B2B exchanges (such as orders and order responses) can be handled quickly and easily. For example, were the sender of a certain message to alter any information, the receiver’s system may be able to update the relevant record automatically in log form (like a ledger) and alert the relevant users immediately to the change. Technically this would be achieved using a purchase order change EDI message.

The role of EDI today

Decades ago electronic data interchange was only used by very large supply chain businesses as the technical setup and maintenance of EDI connections had to be handled completely in-house by specialised teams. Today, however, thanks to the emergence of cloud-based software, the benefits of EDI can be enjoyed by all businesses regardless of size or EDI know-how.

As well as private companies, governments too are turning to data exchange automation in an attempt to reduce costs – particularly those relating to electronic invoicing. As a result, across Europe in particular, new legislation means that having a reliable EDI solution may soon move from being a necessity for large businesses to being a necessity for all businesses.

While it may have been possible for supply chain businesses to survive without a comprehensive EDI solution in the past, this is no longer the case. Without an EDI solution companies risk…

- Loss of business

- Loss of reputation

- Impaired planning ability

- Impaired ability to make informed decisions

- Lack of flexibility

- Non-compliance with new automation regulations

Want to harness the power of successful EDI?

At ecosio, we’ve helped hundreds of businesses to streamline their supply chains and experience the benefits of automated B2B communication.

Through our comprehensive service, which includes building and testing all required mapping and routing, managing partner onboardings from start to finish, and round-the-clock monitoring, we ensure that minimal internal effort is required to achieve an optimal solution. In short, our EDI experts take care of everything so you can focus on what you do best! This way, we not only save

you time and money, but also reduce risk and boost your competitive advantage. If you’re interested in consolidating complex existing processes into one unified cloud-based system, our flexible Integration Hub and fully managed, modular services offer the perfect answer to your problems by providing Connections That Work.

Interested in learning more? Then contact us today!

Image credits

- Convenience Store, 1950s: GNU Free Documentation License, Version 1.2, via Wikimedia Commons

Der Beitrag What is Electronic Data Interchange and What Are Its Benefits? erschien zuerst auf ecosio.

]]>