Der Beitrag Can Increased Automation Build Supply Chain Resilience? erschien zuerst auf ecosio.

]]>- The last five years has seen a surge in recognition by businesses of the importance of building supply chain resilience

- Automating key B2B processes minimises the potential for human error, improves speed, and frees up staff to focus on more valuable tasks

- In a survey of supply chain executives, 88% believe that optimising automated B2B processes can improve supply chain resilience, and over half predicted that efficient automation would improve it “substantially

- 62% of respondents saw automated B2B communication as “very important” to the success of their business moving forward, with none seeing it as unimportant or irrelevant

The last five years has seen a surge in recognition by businesses of the importance of building supply chain resilience. Global events have highlighted the dangers of being unable to react to disruptions, and organisations are increasingly aware of the value of flexibility and adaptability, particularly when it comes to critical B2B processes. Yet despite this, according to a recent KPMG survey, 47% of supply chain executives believe they are still “vulnerable to disruption”.

While there is obviously no way to predict the future, there are pragmatic steps that businesses can take to boost supply chain resilience. Perhaps the simplest and fastest of these to achieve is improving B2B automation. Not only does automating key processes minimise the potential for human error, it can also improve speed and free up staff members to focus on more valuable tasks. In the event of unforeseen circumstances, businesses thus benefit from increased flexibility, as the majority of business-critical tasks aren’t dependent on human intervention.

What our research shows

As part of a wider research project concerning B2B integration trends, we recently conducted our own cross-industry survey in which we asked people their views on the importance of B2B automation.

Of the over 100 supply chain executives we surveyed, 88% believe that optimising automated B2B processes can improve supply chain resilience. Further, over half of those surveyed predicted that efficient automation would improve supply chain resilience “substantially”.

Similarly, 62% of respondents saw automated B2B communication as “very important” to the success of their business moving forward, with none seeing it as unimportant or irrelevant.

What can you do?

Improve and expand automation of business-critical processes! Not only will expanding and optimising automated processes streamline processes and minimise the possibility of human errors, it will also free up internal teams to be able to focus on more value-adding activities.

In particular, introducing electronic data interchange (EDI) and e-invoicing can make a huge difference to the efficiency of day-to-day messaging and drastically improve supply chain resilience.

“As more of the supply chain becomes automated, roles can be redefined to focus on higher-value customer services, and new roles will emerge for humans that drive strategy and innovation.”

Questions to ask yourself

- Are existing B2B integration processes inhibiting your company’s ability to react quickly to market changes?

- Do you currently have business-critical processes that could be automated?

- Are any key supply chain operations reliant on one or two individuals?

- Have you considered investing in a Web EDI solution to extend automation across your entire partner landscape?

- Would internal team members be able to add more value elsewhere if EDI tasks were outsourced?

Want more information on EDI trends?

This article is based on a chapter from our white paper “The Future of B2B Integration – Market Trends Report”, in which we share survey results as well as predictions concerning the evolution of B2B integration. To download your free copy now, simply visit the white paper page and enter your details!

Discover more about our updated product, ecosio.flow.

Der Beitrag Can Increased Automation Build Supply Chain Resilience? erschien zuerst auf ecosio.

]]>Der Beitrag What is Web EDI? erschien zuerst auf ecosio.

]]>Video transcript:

What is Web EDI?

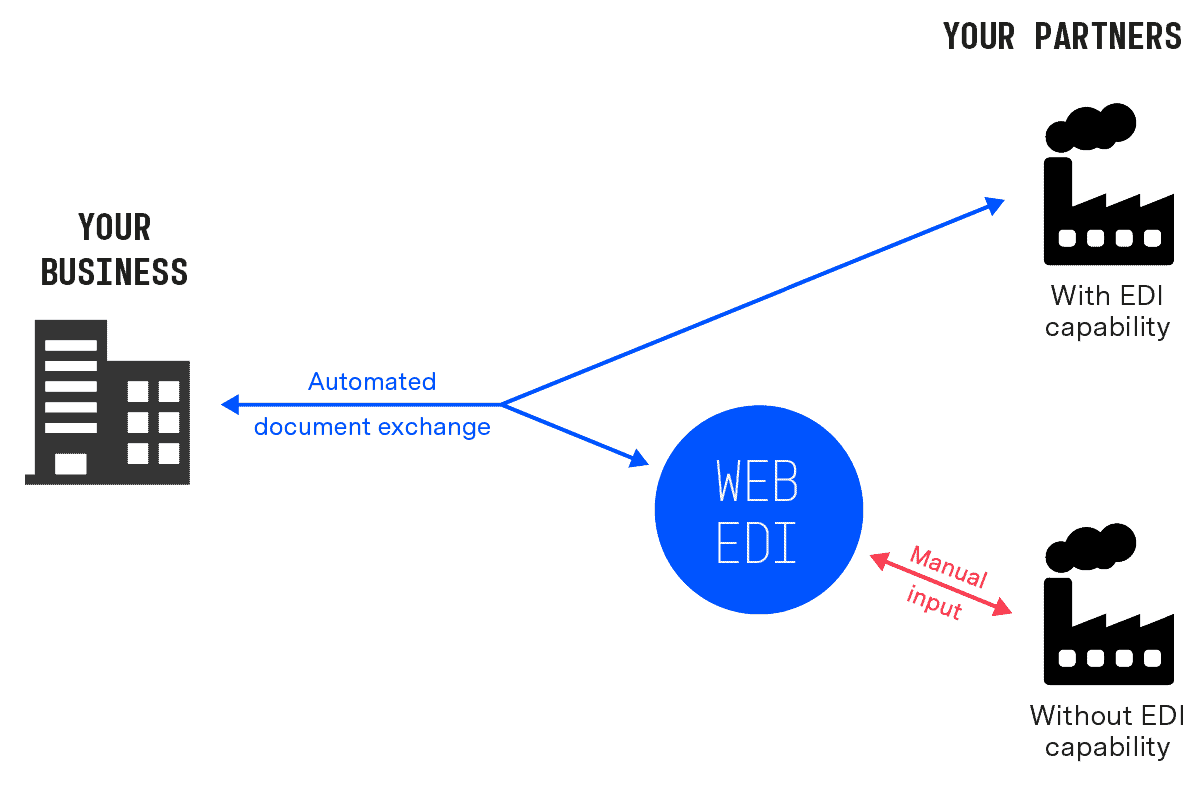

Web EDI is a tool for connecting to suppliers that lack the infrastructure to conduct electronic data interchange (or EDI) in the traditional manner.

In addition to enabling your suppliers to read the EDI messages you send to them, Web EDI allows suppliers to create follow-up documents and return them to you. Web EDI thus enables businesses to extend automation across more of their supply chain.

For your smaller partners it allows simple transmission of EDI documents via a web portal.

For you, meanwhile, deep integration with your ERP system ensures that message exchange via Web EDI looks no different to that via classic EDI.

Why is Web EDI needed?

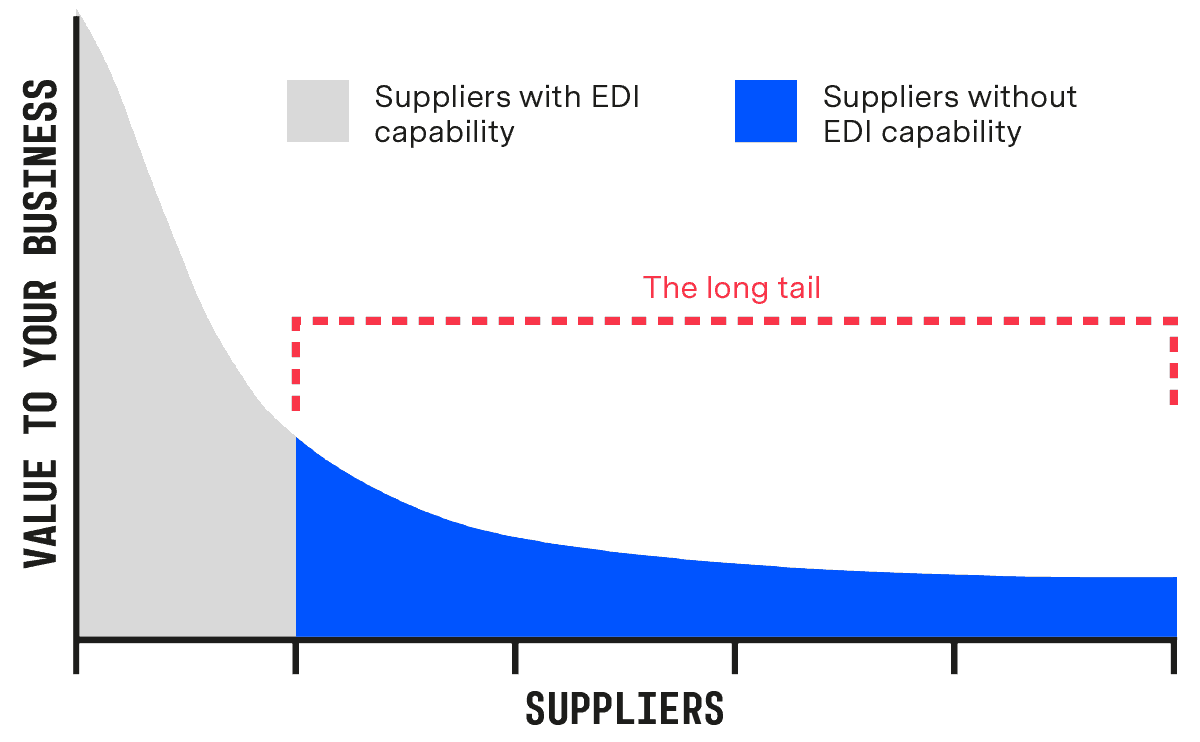

Generally speaking, a supply chain business’s suppliers can be divided into two distinct groups: larger suppliers and smaller suppliers.

- Larger suppliers: Larger suppliers are typically already able to do classic EDI. All that’s required to start exchanging EDI messages with them is for a message implementation guide to be exchanged and mapping and routing to be completed.

- Smaller suppliers: Smaller suppliers on the other hand generally don’t have the ability to conduct EDI and are only able to trade automated messages if their partner provides access to a Web EDI portal.

Although each smaller supplier may not seem significant, when added together, smaller suppliers often constitute a substantial proportion of a business’s partner network (this is referred to as “the long tail”). Communication with smaller partners also typically requires a huge amount of time and effort from internal teams to ensure everything is processed correctly.

An efficient EDI solution should aim for total automation of supply chain communication and should thus cater for both types of supplier. As Web EDI offers the only way to achieve automated exchange of structured documents with partners lacking EDI capability, it is therefore an essential part of a successful EDI solution.

What does using a Web EDI system involve?

So what does using a Web EDI system involve? To answer this let’s examine your perspective and that of a partner using your Web EDI portal.

From your perspective

As far as your ERP system is concerned, once smaller partners have been provided with access to your Web EDI portal, there is no difference between the messages received via Web EDI and those received from larger partners via traditional EDI. All B2B message exchange is automated, with all incoming messages arriving directly into your ERP and all outgoing messages sent directly from your ERP. Essentially no additional work is required (assuming your EDI provider takes care of updates and monitoring).

From your supplier’s perspective

For your suppliers the experience involves slightly more input. First they will be provided with a login to your own tailored portal, within which access rights and alerts can be set as desired.

When an incoming message is received, the supplier is alerted via email to make sure it isn’t missed. The structured data in the EDI message is converted into a human readable format and can be downloaded as PDF. This can then be filed/stored by the supplier as desired.

When sending messages via the portal no EDI knowledge is required either. All the supplier needs to do is enter the relevant information and click send. The portal converts the data into the agreed format and delivers it to your ERP.

Outgoing messages can even be semi-automatically filled with pre-populated information, based on incoming messages. For example, to send an order response the supplier may not need to manually enter any information, as the data will be pulled directly from the incoming order. This process is also known as a “PO flip”.

In the best systems your ERP and Web EDI platform will always be in sync, meaning suppliers will be able to see any order changes in real time. In such systems it may even be possible for individual order changes to be merged automatically.

For example, let’s say you ordered 4 crates of bananas from your supplier initially, but then subsequently wanted to amend this order to cancel one crate of bananas and add a crate of apples.

In a modern system your changes would update the original order in the Web EDI portal directly and notify your supplier instantly.

In addition to reducing the likelihood of you experiencing order issues, the combination of real time synchronisation and automatic data merging makes life much easier for your suppliers.

The benefits of Web EDI

In summary, Web EDI provides several benefits for both suppliers and customers.

For customers the main benefits are…

- A more streamlined partner network

- Cost and time savings through increased automation

- …and reduced pressure on in-house teams

For ecosio customers these benefits are also bolstered by 24/7 platform monitoring, automatic updates and unparalleled data visibility thanks to deep ERP integration.

For suppliers, the benefits include…

- Semi-automated creation of key B2B documents

- The ability to trade with larger partners

- … and access to real-time purchase order information and purchase order changes (in ecosio’s system all order changes can also be merged automatically)

Find out more

At ecosio we are experts when it comes to Web EDI and efficient, automated partner connections. Please click here, if you would like to learn more about our unique ecosio’s Web EDI Solution, or discover more about our updated product, ecosio.flow.

Alternatively, feel free to contact us. We’ll be more than happy to help you experience the benefits of Web EDI and are always happy to answer any questions you may have!

Der Beitrag What is Web EDI? erschien zuerst auf ecosio.

]]>Der Beitrag How Does a Web EDI System Work and What Does It Look Like? erschien zuerst auf ecosio.

]]>To help you understand exactly what Web EDI offers, in this article we’ll run through the basics of how Web EDI works and examine the steps involved in a typical interaction with a Web EDI portal (from the perspective of your suppliers) – namely receiving a purchase order and purchase order changes and returning the relevant documents. First, though, let’s clarify what Web EDI is exactly…

What is Web EDI?

As we explain in our video on this topic, Web EDI is a tool for connecting to suppliers that lack the infrastructure to conduct EDI in the traditional manner. In addition to enabling your suppliers to decrypt your EDI messages to them, it allows partners to add data relating to orders and invoices etc., converts them into structured electronic messages, and transmits them directly into your ERP system.

This way businesses are able to extend automation across as much of their supply chain as possible. For your partners it allows simple transmission of EDI documents via a web portal. Meanwhile deep integration with your ERP system ensures that, for you, message exchange via Web EDI looks no different to that via classic EDI.

Your benefits

- A more streamlined partner network

- Cost and time savings through increased automation

- Less pressure on in-house teams

- ecosio also offers 24/7 platform monitoring and provides updates free of charge

Supplier benefits

- Access to real-time purchase order information and purchase order changes (in good systems all order changes can be merged automatically)

- Semi-automated creation of key B2B documents

- The ability to trade with larger partners

Why is Web EDI Needed?

Generally speaking, a supply chain business’s suppliers can be divided into two distinct groups:

1) Larger suppliers

- These suppliers are able to do classic EDI

- In order to trade automated messages with large suppliers prospective EDI partners must send them a message implementation guideline (MIG) according to their own specifications (in rare cases very large suppliers may be the ones dictating the standards)

Smaller suppliers

- Known as the “long tail”

- These suppliers do not have the ability to conduct EDI

- They are only able to trade automated messages if their partner provides access to a Web EDI portal

Although the majority of messages exchanged may be with larger suppliers, when added together, smaller suppliers often constitute a substantial proportion of a business’s partner network. Communication with smaller partners also typically requires a huge amount of time and effort from internal teams to ensure everything is processed correctly.

An efficient EDI solution should aim for total supply chain communication and therefore must cater for both types of supplier. As Web EDI offers the only way to achieve automated exchange of structured documents with partners lacking EDI capability, it is an essential part of a successful EDI solution.

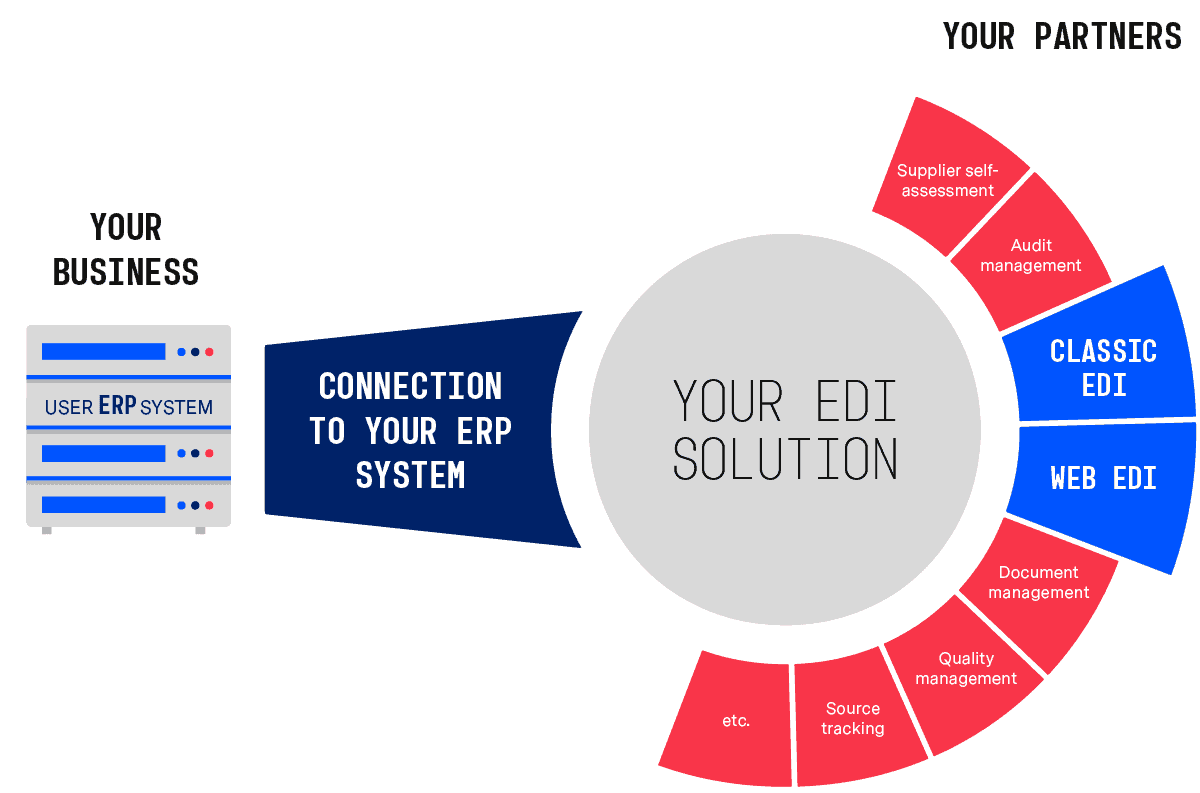

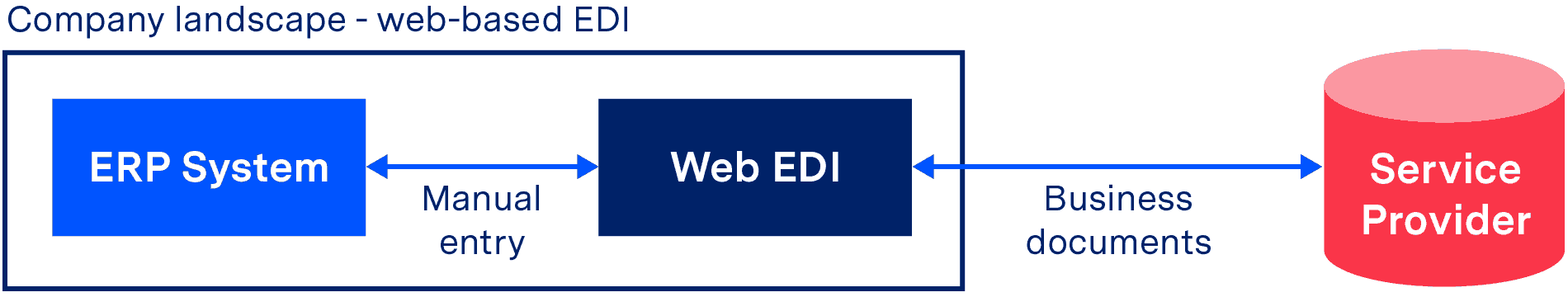

How a Web EDI system works

The diagram below shows how Web EDI fits into a wider B2B integration strategy. Significantly, with ecosio, both classic EDI and Web EDI connections can be established via a single direct connection between your ERP system and ecosio’s cloud-based EDI solution (our Integration Hub). As a result, full end-to-end message visibility is possible regardless of whether your partner has EDI capability or not.

From your perspective

Once smaller partners have been provided with access to your Web EDI portal, as far as your ERP system is concerned there is no difference between the messages received via Web EDI and those received from larger partners via traditional EDI. All B2B message exchange is automated, with all incoming messages arriving directly into your ERP and all outgoing messages similarly sent directly from your ERP. To see what a Web EDI system actually looks like, see our article “How Does a Web EDI System Work and What Does It Look Like?” on this topic.

From your supplier’s perspective

Once your Web EDI platform has been created your suppliers will be provided with a login to your own tailored portal. Within this portal access rights and alerts can be set as desired.

Incoming messages: The supplier is informed by email when a new message arrives, meaning none are missed. Structured data is presented in a human readable format

and can be downloaded as PDF.

Outgoing messages: Can be semi-automatically created with pre-populated information, based on incoming messages (e.g. turnaround process from order to order response)

Below is a step-by-step example of a typical interaction of a partner and their Web EDI portal:

- They receive a notification that a purchase order has been received

- They log on to view the purchase order (with a deep link in the email)

- It can be downloaded as a PDF and printed

- A purchase order response is generated

- A dispatch advice is generated

- An invoice is generated

- Once checked, these documents can be sent with a single click

Why supplier experience is important

Although the usability of your Web EDI portal may not seem like a key concern as you won’t be using it yourself, it is important to note that a poor user experience can impact on the quality of the output you get via it from your partners.

The less information your supplier needs to enter, the fewer errors they are likely to make. If your portal is able to streamline the turnaround process by semi-populating key documents automatically for your suppliers, meaning all that is required is for them to check the information and send, there is little chance of errors occuring. In addition, a good system (such as ecosio’s) should enable the customer to determine which fields their suppliers can edit and offer validation to ensure only correctly formatted messages can be transmitted.

The simpler your Web EDI is to learn how to use, the faster new onboardings can be completed, and the happier your suppliers are likely to be with your relationship moving forward.

Admittedly, no matter how user friendly the portal is, Web EDI will never be as smooth as classic EDI for the supplier given the fact that manual data entry is still required to some extent. Therefore, if orders with a certain supplier increase substantially, they may wish to transition to doing traditional EDI to reduce manual effort on their side. As a fully managed service provider, ecosio can handle this transition from start to finish with zero disruption to you and your partners.

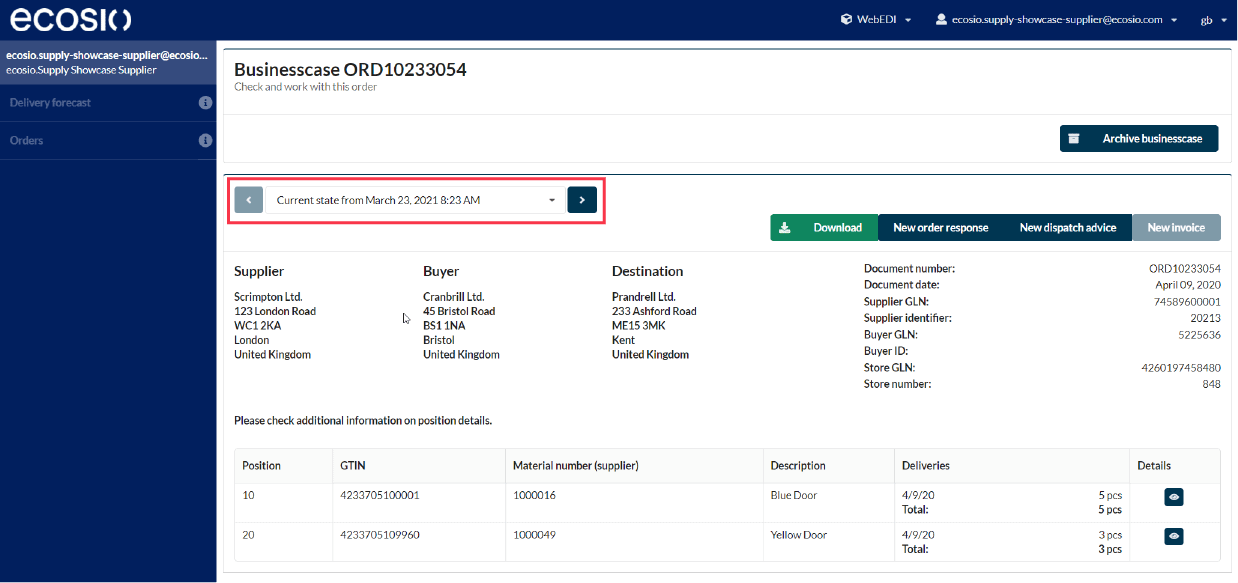

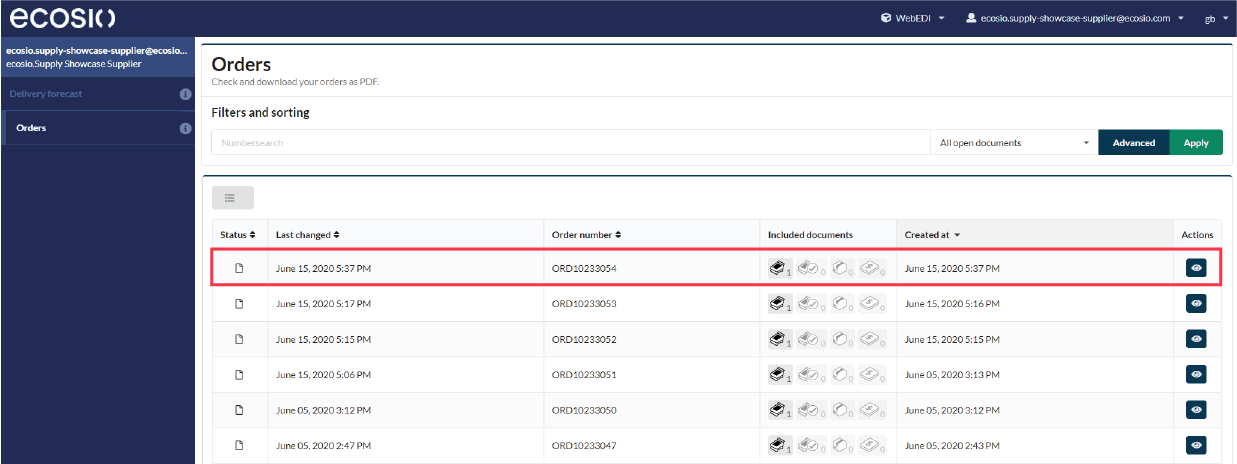

Now let’s look at an example of what a good system looks like from a supplier’s perspective…

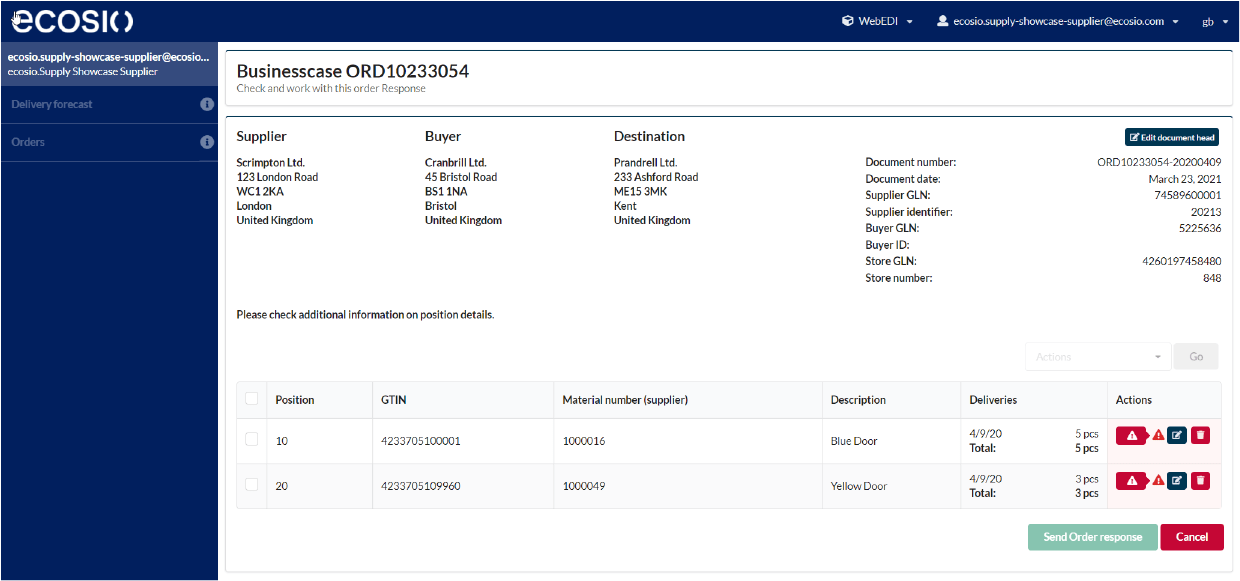

Example – responding to a purchase order

When an order comes in, the individual can access their portal and select the new order from the overview screen. Users will also receive a notification email containing a direct link to the new order.

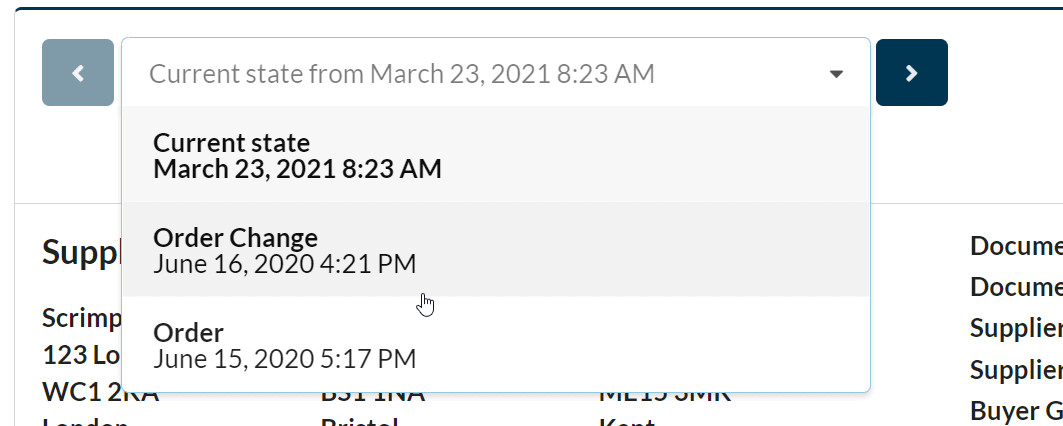

When the order in question is clicked on (highlighted in the above image), only the most up-to-date information is displayed (see image below).

Clicking the dropdown menu highlighted in the above image shows a chronological list of order changes and amendments (shown below).

Sending the order response simply requires the user to click “New order response”. This then takes them to the below screen where they are able to edit or amend the details if necessary (for example if the supplier needs to confirm delivery of a reduced number of goods) – though this of course requires customer consent first. Once everything has been checked, the user just needs to click the “Send order response” button.

The same simple process applies for both an invoice and a dispatch advice.

Once sent, order responses are visible at the bottom of the order detail page. Meanwhile an icon also appears on the order overview screen.

Want more information?

This article is based on our white paper “Can Web EDI Really Transform My Supply Chain?”. In this comprehensive white paper we look in detail at what Web EDI is, the challenges of Web EDI systems, how partners are connected, and what makes a good system.

Download your free copy of “Can Web EDI Transform My Supply Chain?”, simply submit your details.

Discover more about our updated product, ecosio.flow.

Alternatively, if you have any questions about your particular situation or anything else EDI related, feel free to get in touch! We are always happy to help!

Der Beitrag How Does a Web EDI System Work and What Does It Look Like? erschien zuerst auf ecosio.

]]>Der Beitrag Three Challenges for Web EDI Solutions erschien zuerst auf ecosio.

]]>However, underneath this overarching requirement are three key challenges that successful Web EDI solutions must overcome to provide maximum benefit to customers…

[Need a reminder of the basics of Web EDI first? Check out our video on this topic!]

1) Providing access to real-time information for everyone

In order for a partner connection to function at maximum efficiency, suppliers must have access to up-to-date purchase order information, including purchase order changes (e.g. resulting from a shift in demand from the end customer). Suppliers should also be given the opportunity to send electronic purchase order responses as well as dispatch advices and invoices. Compared to traditional paper-based exchange processes, such a system produces vastly improved data visibility for all parties.

With ecosio’s solution purchase order changes are automatically reconciled with the original purchase order. Thus, the supplier always has the most recent information at hand.

2) Minimising partner effort

Although most businesses’ main concern when investing in a Web EDI solution is minimising manual effort on their own end, it is also important that the portal is as useful as possible for your partners, as this will result in better takeup.

By semi-automatically generating purchase order responses, dispatch advices and invoices where possible, the likelihood of errors being introduced through manual input is virtually eliminated.

ecosio’s Web EDI solution aims to reuse as much information as possible from the original purchase order to maximise efficiency. Consequently, a purchase order response may be created based on the data from the underlying purchase order; a dispatch advice may be created from the data from the underlying purchase order or the purchase order response; and an invoice may be created from the underlying despatch advice (or from the purchase order if no despatch advice is being used). Meanwhile ecosio’s sleek and clean user interface allows for easy data processing.

3) Flexibility of Web EDI solutions

The third key challenge for Web EDI solutions is flexibility. For example, if a supplier using your Web EDI wants to switch to classic EDI your solution should be able to cope. Similarly, if new document types (e.g. DELFOR for delivery forecasts) are required, integration of these should be possible.

You may also want to bolster your solution moving forward by adding Supplier Relationship Management (SRM) features such as audit management or supplier self-assessment modules. This is made much simpler if you have an EDI solution that can grow as your needs evolve.

ecosio’s Web EDI solution is capable of being supplemented by many key SRM features – each of which can be purchased and combined in modular fashion as required. This means that no matter how much your requirements change over time, your solution can be adapted accordingly, ensuring it stays as efficient and valuable to your business as possible.

Want more information?

This article is taken from our white paper “Can Web EDI Really Transform My Supply Chain?”. In this white paper we also explore the benefits of Web EDI, how partners are connected, what a good system includes, and the importance of considering future needs. For those interested in seeing what a Web EDI system looks like in practice, we also provide a breakdown of a typical action including screenshots.

Download your free copy of “Can Web EDI Transform My Supply Chain?”, simply enter your details.

Or click to discover more about our updated product, ecosio.flow.

Alternatively, if you have any questions about your particular situation or anything else EDI related, please do not hesitate to get in touch! We are always happy to help however we can.

Der Beitrag Three Challenges for Web EDI Solutions erschien zuerst auf ecosio.

]]>Der Beitrag Supplier EDI Onboarding – The Seven Key Steps erschien zuerst auf ecosio.

]]>With this in mind, in this article we will take you chronologically through a thorough supplier EDI onboarding process, from kick-off to go-live – looking at what’s needed from you and your suppliers along the way. Hopefully by the end you will know exactly what a successful project involves and be more confident in making the right choice of solution.

Step 1 – Kick off and definition of EDI requirements

Unsurprisingly the first step in any supplier onboarding project is for your provider to identify exactly what it is that you want. Though there is no one way to achieve this, it is generally best if both you and your EDI provider have a clear point of contact, as this will increase the project’s speed and efficiency.

Once your internal team has been agreed, your provider will liaise with them to find out what your requirements are. This involves discussing:

- Processes – How are orders, deliveries and invoices handled?

- Document types – What document types need to be realised? For example, are you looking to trade invoices only, or do you also want to exchange other common document types, such as orders and despatch advices (aka INVOIC, ORDER and DESADV for EDIFACT messages and 810, 850 and 856 for X12 messages, for example). More sophisticated EDI integrations will also enable automated transmission of sales data reports (SLSRPT / 818), inventory reports (INVRPT / 846) and receiving advice messages (RECADV / 861).

- Message data granularity – Which data elements do you want to be included in each message? In addition to the basics (price, quantity, article number) do you require additional information, such as descriptions or best-before dates?

- Message / process semantics – What is the structure and content of your exchange messages? Usually the ERP system has a preferred (data model) exchange format. This needs to be communicated to the EDI provider for the creation of the dataΩmapping.

- Message protocols – How is your EDI data exchanged with your back-end system? This can be handled via a number of different protocols, such as API, SFTP and HTTPs.

It is tough to give an estimate of how long this process will take given the bespoke nature of the process, but if you are aware of your requirements in advance and have assigned a dedicated project leader internally, this step can take as little as a couple of days. Usually the process will take longer than this, however, and typically involves a fair amount of back and forth.

Step 2 – Creation of Message Implementation Guide (MIG)

Having completed the fact-finding step, your EDI provider will then create your message implementation guide (or MIG). A MIG is basically a ‘how to’ guide for your partners which details your business’s EDI requirements and the specifics of your preferred message formats etc. This normally takes around two days of work per MIG to complete.

As the success of this step has a knock-on impact on the success of the rest of the EDI onboarding process, it is particularly important that this is completed carefully. To ensure the reliability of the MIG, fully managed EDI providers, such as ecosio, will send sample messages to your system. They may even enlist the help of one of your close suppliers to conduct a parallel phase to check everything is functioning correctly. All that is required on your side is to check the messages and flag if anything needs altering.

Sadly, with non fully-managed EDI solutions this phase is often rushed, with little or no testing conducted, leading to errors further down the line.

Step 3 – Creation of Web EDI platform

If you are looking to automate as much as possible of your supply chain’s document exchange, you may also intend to connect suppliers who do not have EDI capability using Web EDI (see our white paper for more information on Web EDI and how it can benefit you).

If this is the case, it is important that the scope of your Web EDI platform matches the scope of message types used with suppliers via “classic” integrated EDI. For example, you may need to exchange non-mainstream documents such as SLSRPT, INVRPT or RECADV in addition to orders, despatch advices and invoices – in which case care should be taken to select a provider, such as ecosio, that can support this (as this functionality is rare).

Your Web EDI platform will be built in parallel with the creation of your MIG(s). This process involves a one-time connection of the EDI solution to your ERP system and subsequent configuring of the platform to meet your requirements. Your supplier should be able to send test documents via the platform according to your MIG (for you to then check). As with the creation of the MIG, you may also want to enlist the help of a close supplier to help test the platform before wider rollout.

As Web EDI requires suppliers to put in manual effort in order for you to experience full automation, platforms are not always hugely popular with suppliers. As a result, selecting a Web EDI system, like ecosio’s Web EDI solution, which is able to minimise effort on your suppliers’ side through features such as semi-automatic document creation, PDF printing and batch support can greatly increase take-up across your supply chain.

Step 4 – Prioritising / approaching your partners

Once your MIG and Web EDI platform have been created it is time to begin onboarding your partners. Before approaching them, however, it is important to agree a strategy with your EDI provider. With large supply chains, it can take a while for partners to be onboarded. As such it makes sense to prioritise onboarding certain partners first so you get maximum benefit from your new system. For example, you may wish to prioritise your biggest suppliers, or those with whom you are closest. As your EDI solution provider will have handled similar projects many times before, they should be able to offer valuable input here.

Once the supplier EDI onboarding strategy has been agreed, your provider should approach each supplier to clarify details such as identifiers (e.g. GLN number), current capabilities (e.g. what types of documents they can exchange via EDI) and which type of connection they would prefer (e.g. AS2, X.400, VAN etc.).

During this process your EDI provider should also share your new message guidelines with your suppliers, allowing them to know what your system requires and how to create valid outgoing documents, which brings us on to…

Step 5 – Message exchange testing / validation

The testing phase involves your provider sending your supplier documents in order for them to send back the necessary responses (e.g. an Order and Order Response).

If your supplier returns an incorrect message they should be informed by your provider what the errors are, enabling them to be corrected. This is known as validation.

Validation can be done manually by checking the message against the MIG. This is a tedious and error-prone method, however. Instead, validation is better handled automatically, by employing in-built validation checks on the integration software, or semi-automatically, by using external software capable of checking message syntax.

Automatic checks (such as those completed by ecosio’s cloud-based EDI solution (our Integration Hub)) can immediately return error reports via email or web portal to the document issuer. Manual checks, on the other hand, involve much more effort, meaning more time until the error report is ready

Once any errors have been corrected and your supplier is able to send a response that conforms to your MIG, the message will be sent to your internal team to check. If a fully managed provider is opted for, this checking should be the extent of the input required from you.

Step 6 – Go-live

When you are happy with the responses from your supplier the connection can be put live. In some cases you may wish to run a parallel phase (alongside a continuation of your previous message exchange method), for several months to ensure that everything is functioning smoothly.

With suppliers being connected via Web EDI the process is even simpler, as they simply need to be activated on the platform. If your Web EDI portal is sufficiently intuitive / user-friendly, training may not even be needed. Alternatively it can be provided in the form of pre-recorded videos / documentation.

Step 7 – Post go-live

Whilst go-live might well signal the end of the EDI onboarding process, it is far from the end of the work when it comes to ongoing document exchange with your partners. For example, your supplier may conduct (as ecosio does) ongoing validation mapping checks to ensure that message details match the requirements of your MIG – thus avoiding the complications associated with incorrect details being transmitted to your ERP.

In order to benefit from a successful and future-proof system, processes also need to be in place covering message monitoring and error handling. Significantly, with many solutions go-live effectively signals the end of your EDI partner’s active involvement, meaning these responsibilities fall to internal teams. However, this is not the case if a fully managed EDI provider such as ecosio is opted for.

Ideally your EDI provider will continue to oversee your business’s EDI connections, acting as a point of contact for your suppliers (both those using classic EDI and Web EDI) and working proactively to correct errors and ensure connections are functioning at maximum efficiency. This way you benefit from both more reliable EDI and the time and cost savings associated with less pressure on internal teams.

As your needs are likely to change over time, it also makes sense to consider investing in a solution that can adapt alongside your business. For example, clients of ecosio are able to add additional Supplier Relationship Management (SRM) modules as required.

Discover a fully managed approach to EDI onboarding with ecosio

As every supply chain is different, every business faces unique challenges when it comes to connecting to suppliers. To be successful, electronic data interchange requires not only technical expertise during set-up and onboardings, but also ongoing time and effort in the form of message monitoring, error handling and installation of updates etc. after go-live. Simply put, each of the steps we have covered is crucial to the lasting health and reliability of your EDI connections.

At ecosio we understand the effort involved in establishing and maintaining efficient EDI, which is why we aim to help businesses avoid the time and stress it can cause by minimising internal effort. As well as making sure connections are as secure as possible through conducting thorough testing, ecosio’s experts manage the entire EDI onboarding process, from kick-off to ongoing operation (unlike other providers). Essentially we do the work so you don’t have to! The upshot is a more cost-effective outcome, faster connections and peace of mind.

To find out more about ecosio’s fully managed solution and how we can help you benefit from simple, efficient and intelligent EDI, contact us today! We are always happy to answer your questions.

Der Beitrag Supplier EDI Onboarding – The Seven Key Steps erschien zuerst auf ecosio.

]]>Der Beitrag Web-Based EDI vs Fully Automated EDI: What’s the Difference? erschien zuerst auf ecosio.

]]>Unfortunately, despite being well aware of the issues with web-based EDI, many businesses neglect to consider moving to a fully automated solution as they are either unaware of the substantial benefits of doing so or believe migration will be extremely complicated.

Admittedly, identifying the benefits of moving from a web-based to a fully automated EDI solution, and when best to do so, can be tricky, with different providers all saying different things. To help elucidate, this article explores the real difference between web-based and fully automated EDI, providing you with a clear picture so you can make the right decision for your business moving forward.

Starting out – web-based EDI

For many businesses, the first interaction with EDI comes as a result of a large retail customer requiring EDI capability from their trading partners. In order to enable their suppliers to trade with them efficiently, these larger customers will generally provide access to a web-based EDI portal.

Naturally, as supply chain businesses grow, so do their trading partner networks. As such, in time many smaller and mid-sized suppliers quickly find themselves having to manage B2B data exchange via multiple web-based EDI portals. This in turn can compromise growth, efficiency and profits, as exchanging commerce critical information becomes increasingly complicated and resource-heavy.

Where most businesses go wrong

Unfamiliar with the key differences between web-based EDI and fully automated solutions, many organisations purchase their own web-based EDI package in order to simplify document exchange by removing the need to access multiple customer portals. However, while this consolidation admittedly saves some time, it fails to combat the main business problem that EDI was developed to fix – time-consuming and error-prone manual data entry.

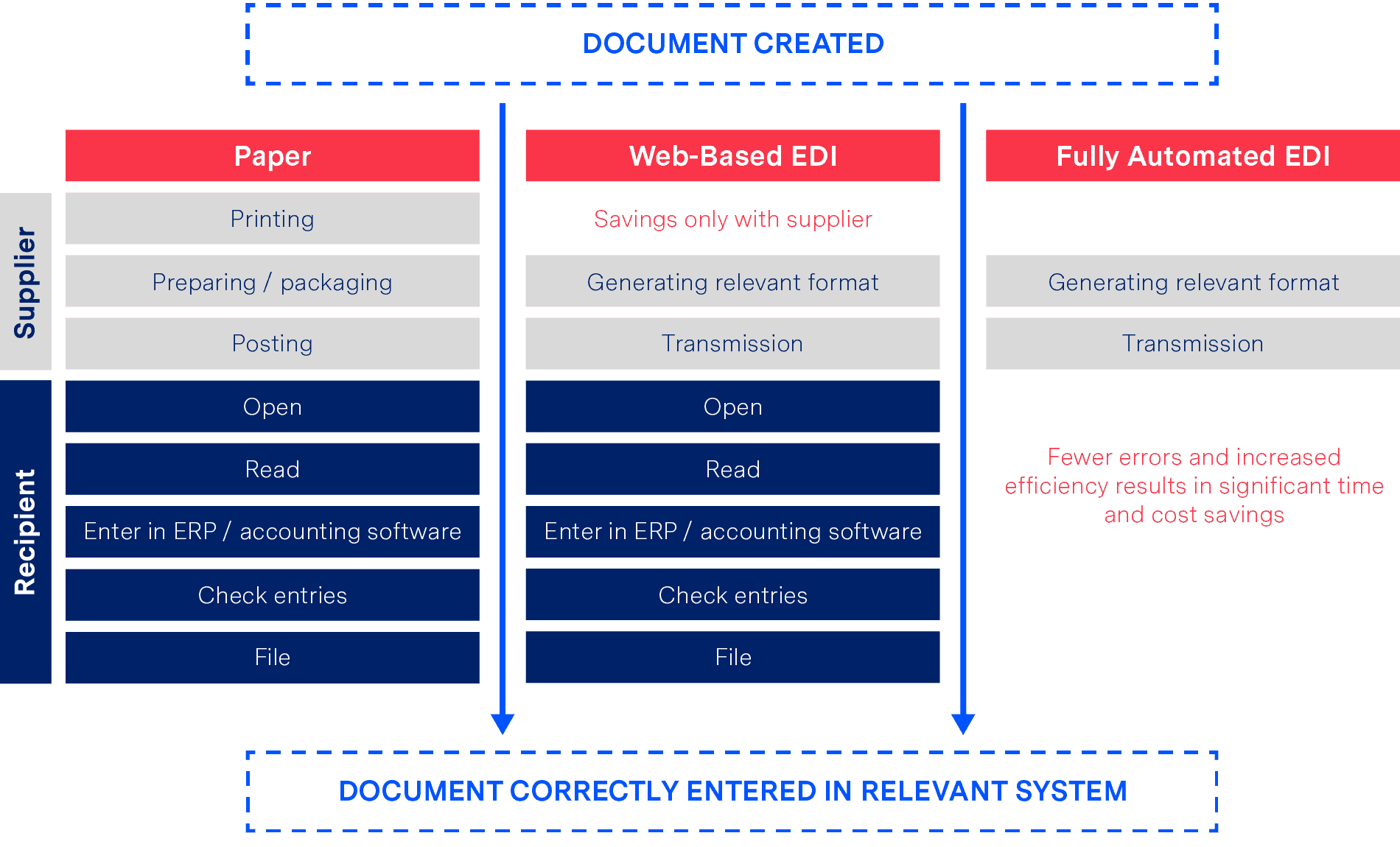

As illustrated in the diagram below, although the communication between your web-based EDI platform and your partners may be automated, seamless integration between your EDI portal and your ERP system is not possible. This means that all information must be manually transferred. In essence you’re paying to do business with those customers who require EDI, without experiencing any of the benefits of EDI yourself.

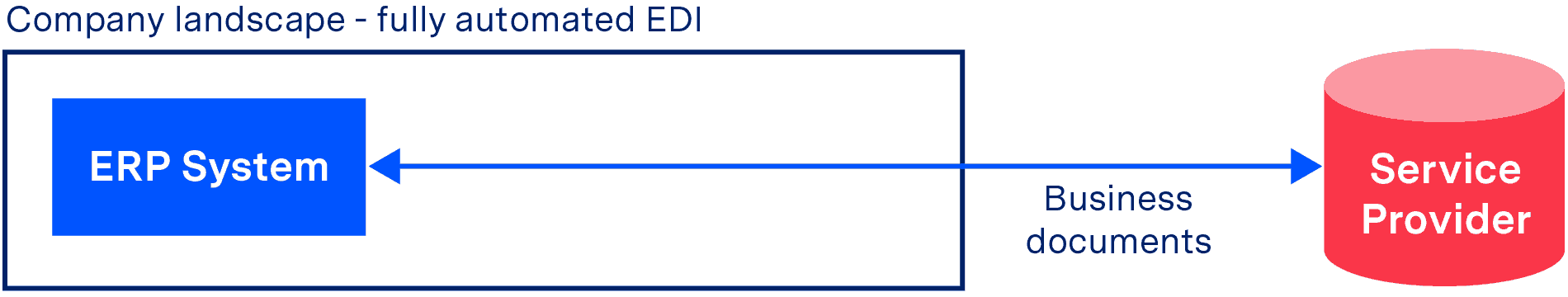

How does fully automated EDI differ from web-based EDI?

The key difference between web-based and fully automated EDI is the fact that the latter allows your business partners’ ERP system effectively to talk directly to your own, bypassing the need for human intervention. Individual documents are then automatically available in your ERP system and can be searched for and edited in your existing user interface.

By removing the need for manual data entry, both error rate and pressure on internal teams are greatly reduced.

“What are the cost implications?”

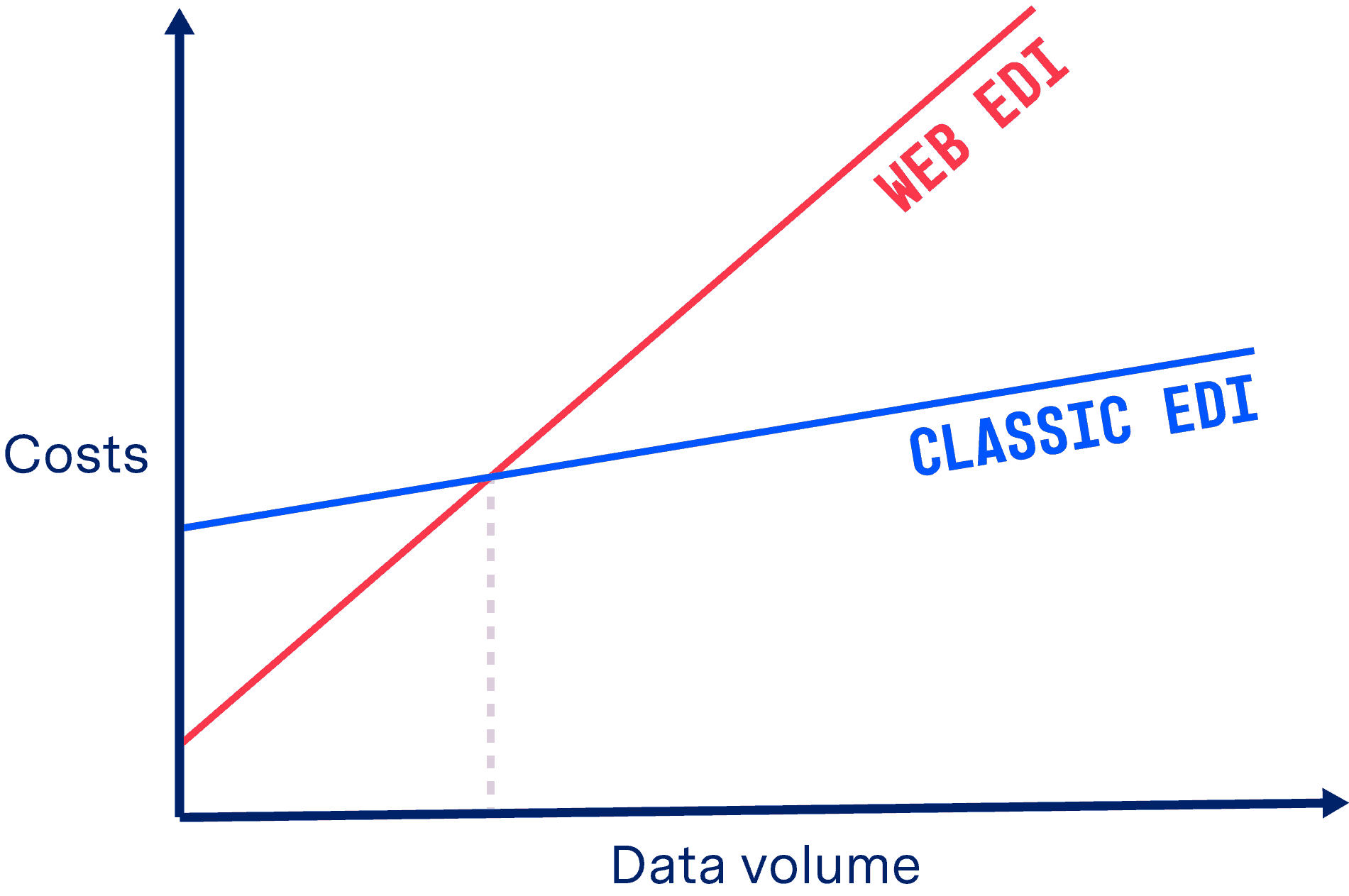

Although Web EDI offers suppliers the benefit of being able to expand their partner networks to include larger retailers, in terms of the cost-effectiveness of processing documents, web-based EDI is virtually the same as traditional paper/PDF communication.

As illustrated in the figure below, the only real saving of moving from paper-based document exchange to Web EDI is printing costs. On the other hand, moving from web-based EDI to fully automated EDI drastically reduces the number of steps to process a document. Thanks to seamless integration in the user’s ERP system, fully automated EDI requires only two steps for successful end-to-end exchange: generation and transmission.

While estimating the cost benefits of this process improvement is complicated, based on numerous reports from IBM, GS1 and others, the expected savings of moving to a fully automated system can be calculated at around 64%. This figure factors in FTE costs, opportunity costs of more value-adding activities, errors, delays and postage/fax fees (if relevant).

As we look at in our blog post on the topic, however, perhaps the biggest factor when it comes to achieving cost savings is making the right EDI supplier choice.

How is this process improvement achieved?

The key factor behind this streamlining of B2B document exchange is deep ERP integration.

Opting for a managed EDI solution offering deep integration (as opposed to relying on customers’ web-based EDI portals) means that when it comes to monitoring, accessing, troubleshooting or modifying messages, you can do it all directly in your ERP system. This allows businesses to self serve – avoiding delays and relieving pressure on in-house resources.

Unlike many other providers, ecosio offers deep ERP integration, creating a seamless UI experience thanks to our unique and powerful API. With several connectors capable of creating a fast link between ecosio and any ERP system, achieving unparalleled message status visibility is a simple process.

Differences at a glance

| Web EDI | Fully automated EDI |

|

|

“So when should I make the switch?”

In general, a classic EDI solution is always preferable to a Web EDI solution, because only with classic, managed EDI can the full automation potential of electronic data exchange be realised. However, in practice the transition to a fully automated system usually comes after a period of using web-based EDI portals.

As shown in the figure below, the use of web-based EDI becomes uneconomical beyond a certain volume of documents (and increasingly so as document volume increases over time).

Want to learn more?

Discover more about our updated Web EDI product, ecosio.flow.

If you are a supplier looking to move from your customers’ web-based EDI portals to experiencing the benefits of fully automated EDI yourself, get in touch today. We’re happy to answer any questions you have!

Der Beitrag Web-Based EDI vs Fully Automated EDI: What’s the Difference? erschien zuerst auf ecosio.

]]>