Der Beitrag The Most Common ANSI ASC X12 Parties and How to Use Them erschien zuerst auf ecosio.

]]>If you are not already familiar with X12 file structure and ANSI messaging terminology, you may wish to read our article on the structure of an X12 file before continuing.

If you use EDIFACT instead, read our article on using EDIFACT parties.

What are ANSI X12 parties?

As their name suggests, party identifiers are used in X12 messages to identify certain X12 parties in a particular transaction, such as the shipping party or the receiving party. The party can be an organizational entity, a physical location, property or an individual. The identifiers themselves sit at the start of an N1 segment and are 2-3 characters long.

The full list of X12 party identifiers includes over 1,300 different parties, however most exchanges will only require a few of these. The most commonly used identifiers are listed here:

| ANSI Party Identifier Code | Identifier description |

| N1*BY | Buying Party (Purchaser) |

| N1*SU | Supplier/Manufacturer Party |

| N1*SF | Ship From Party |

| N1*SO | Sold To Party |

| N1*ST | Ship To Party |

| N1*MI | Planning Schedule/Material Release Issuer Party |

| N1*BT | Bill To Party |

For completeness, we have also included the full list of X12 party identifiers at the bottom of this article.

Why is getting X12 party identifiers wrong a common issue?

Within the ANSI ASC X12 standard, there are a multitude of different possible parties that can be involved in a certain transaction. Some of these X12 parties may, in certain cases, be the same as other parties. For example, Bill To and Ship To could easily contain the same information in a particular transaction. Crucially, however, this will not necessarily be true for other transactions.

Unfortunately, confusion over this (or exactly what each party identifier refers to) can lead to poor master data maintenance and incorrect data being exchanged.

Why getting X12 parties right matters

If the correct X12 parties aren’t used, sooner or later errors will occur. These errors can have significant consequences and cost implications. Larger partners, for example, will refuse any invoice that contains data that doesn’t match their records.

Further, correcting master data issues once an issue has been discovered can be time consuming and complicated.

What can I do to avoid using identifiers incorrectly?

In order to avoid future issues, those using X12 parties should…

- Double check the EDI message implementation guideline or “MIG” (and any other relevant documentation) to ensure parties are being used as intended.

- Cross check with other messages in the same chain in case there are interdependencies. For example, an X12 invoice message will usually include the same party identifiers as the preceding order or despatch advice message, but may also include other X12 parties too.

If in doubt, simply check with your partner or EDI service provider. It is always better to ask and get it right first time than to assume.

Want more information?

If you would like more advice on using ANSI ASC X12 parties correctly or streamlining B2B integration more generally, please get in touch. We are always happy to help!

Our resources section also houses a wide selection of articles, webinars, white papers and infographics that you may find useful.

Der Beitrag The Most Common ANSI ASC X12 Parties and How to Use Them erschien zuerst auf ecosio.

]]>Der Beitrag What is Master Data Synchronisation and Why is it Needed? erschien zuerst auf ecosio.

]]>Thankfully, it is possible to eliminate data issues across individual partner connections by conducting a master data synchronisation (or master data sync). In this article we look at what a master data sync is, why it’s needed, where people often go wrong, and the correct way to handle one.

What is a master data synchronisation?

A master data sync is a process in which you and your business partner examine your master data to ensure that you are both using the same master data elements and the same information for each element.

Data must be consistent within each individual message exchange and across multiple exchanges to ensure streamline B2B integration. Usually, EDI heavily builds on unique identification numbers for all involved parties, goods and services and does not rely on natural language descriptions. E.g. one does not refer to a supplier as “Supplier A Ltd” or a customer as “Customer B Inc.”. Instead unique IDs are used, which must be known to all involved parties. For example, if you refer to a supplier as “A” and a customer as “B”, your partner must adopt the same identification approach to avoid your ERP system (and theirs) pulling through the wrong information from EDI messages.

Typically it is the larger partner – i.e. the “onboard-er” rather than the “onboard-ee” – that dictates what should be used.

Why is syncing master data important?

EDI messages save businesses a significant amount of time and money by optimising B2B processes through automation. If master data is not aligned, however, data errors will occur – and worse still, these errors may not be immediately obvious.

If spotted, errors can be fixed through time-consuming manual intervention. If not spotted, simple errors such as an incorrect delivery address for a large order can ultimately disrupt your entire supply chain and cost your business dearly.

Syncing master data thus provides peace of mind and helps ensure your supply chain runs smoothly.

When should I do a master data sync?

Master data should always be synced before a partner onboarding and whenever there is a change/update of master data on the side of one partner that is relevant to the other partner. This way there is a much reduced risk of errors happening once your connection is up and running. The mapping process is also much faster and simpler when master data has been synced in advance.

What are the most commonly used master data elements?

While master data can extend to include whatever data you want, the most common types of master data in the context of EDI are as follows…

Mailbox IDs (AKA technical sender / receiver information)

This is the ID of the mailbox that the invoice (or other message) is sent to. It is not the same as the invoice recipient or the delivery point. Essentially the Mailbox ID is like the information you put on an envelope; it may not bear any resemblance to the information contained in the letter inside. Though often overlooked, Mailbox ID is an important master data element and should be stored in the ERP system along with the above elements.

Usually unique IDs such as Global Location Numbers (GLN) or DUN & Bradstreet Numbers (DUNS) are being used. However, bilaterally agreed IDs are also possible.

The following example shows two mailbox IDs in action in an EDIFACT purchase order message.

UNA:+.? ‘

UNB+UNOC:3+7810029032309:14+7347339003422:14+211025:1750+138841++ORDERS+++4711′

UNH+1+ORDERS:D:01B:UN:EAN010′

In the example above 7810029032309 uniquely identifies the sender’s mailbox and 7347339003422 the receiver’s mailbox. Both IDs are Global Location Numbers (GLN).

Involved business partners and their IDs

As with Mailbox IDs, unique IDs such as GLN or DUNS numbers are being used to identify business partners. In some scenarios custom IDs, such as the customer’s business partner IDs can be used as well (though this is discouraged by EANCOM).

The following example shows two business partners in an EDIFACT message.

NAD+BY+7870037600032::9′

NAD+SU+7365339000045::9′

The first line identifies the buyer using a GLN and the second line identifiers the supplier using a GLN.

Usually, EDI files contain some of the following roles (non exhaustive list):

- Supplier – The party supplying the item(s) being purchased.

- Customer / Buyer – The party purchasing said item(s).

- Delivery point / Ship to – The delivery address (this should not be confused with any other address connected with the customer).

- Ultimate consignee – The party that will ultimately receive the final item(s).

- Invoice recipient – The party that receives the invoice. Significantly this is not necessarily the customer. For example, if a shop was to buy something, the invoice recipient may well be their headquarters rather than that particular shop.

For more information on the various parties used in EDIFACT, see our blog post on how to use EDIFACT parties correctly.

Usually, an EDI message exchange consists of multiple different messages, e.g. in case of EDIFACT:

- ORDERS (Purchase Order)

- ORDRSP (Purchase Order Response)

- DESADV (Despatch Advice)

- INVOIC (Invoice)

In such a case it is important that the used IDs remain consistent among the exchanged document types. If the buyer is identified in the original ORDERS message as for instance:

NAD+BY+7870037600032::9′

…the exact same GLN 7870037600032 must be provided as the NAD+BY in all other consecutive messages as well (ORDRSP, DESADV, INVOIC).

Exchanged material and service identifiers

The materials or services associated with an EDI message are identified using a unique number as well. Instead of using the supplier’s article numbers or the customer’s article numbers, usually a globally accepted and unique system is adopted. Similar to Global Location Numbers (GLN) for identifying the involved parties and mailbox IDs in EDI, Global Trade Identification Numbers (GTIN) can be used to uniquely identify exchanged goods and services. Oftentimes a combination of both is used – e.g., GTINs are used alongside with the supplier’s article numbers. Thus, the receiving system can be built on any of the two numbers.

The following examples shows an exemplary line item from an EDIFACT message.

LIN+1++4347256156543:SRV’

PIA+1+3345005260:BP’

PIA+1+34559560323:SA’

IMD+F++:::STRAWBERRIES 5X1KG RB’

The first line is the GTIN of the exchanged product. In addition the second line provides the buyer’s article number and the third line the supplier’s article number. Line four contains the free text description of the product for informational purposes only.

These are only a handful of the many possible master data parties. Different industries have different essential master data parties, and some businesses prefer to exchange more granular data than others. For example, the full codelist for parties in EDIFACT can be found here. Please note that different EDI standards use different codes/names for master data parties.

Where people go wrong

Just as IT systems and EDI solutions typically grow and evolve over time, so master data, too, is often historically grown. Over the years it is common for certain master data fields to be conflated, with conflation of a company address and delivery location being possibly the most common example.

Another very common issue concerns the use of the “technical sender / receiver” (AKA “Mailbox ID”) element, which may be, but crucially does not have to be identical to the IDs used in the EDI message.

But master data errors can happen across any of the hundreds of different master data parties. What’s more, these errors will multiply over time unless necessary measures are taken. As a result, by far the biggest master data mistake companies make is not conducting a thorough master data sync before a new onboarding.

Who should handle a master data synchronisation?

While it may seem like your EDI provider would be the most logical candidate to handle master data synchronization, in reality the best person to handle such a project is the person best acquainted with the data and how it is used by your business. Although your EDI service provider may be very knowledgeable about your partner connections, they would only act as a middleman in a master data sync project as they are not able to make key business decisions when it comes to how you want data to be used/stored. The fastest and most efficient way to complete such a project is through direct communication between the employees with the most relevant experience in both you and your partner’s organisations.

However, your EDI provider may certainly help you with decisions on how and where to store EDI IDs in your ERP system. In particular if deep EDI/ERP integration solutions are used, such as ecosio’s integrations for ERP systems like SAP, Microsoft, Infor and the like.

Want more information?

If you would like help or advice on master data, partner onboarding, or any other EDI topics, please get in touch. We are always happy to help!

You can also find a wide selection of articles, webinars, white papers and infographics in our resources section.

Der Beitrag What is Master Data Synchronisation and Why is it Needed? erschien zuerst auf ecosio.

]]>Der Beitrag What is Master Data and Why Does it Matter? erschien zuerst auf ecosio.

]]>The answer to these problems lies in ensuring your business has reliable master data. But what is this exactly, how can accurate it impact your B2B processes, and what does a good master data system look like? Let’s explore…

What is master data?

Master data, as the name suggests, is the most important data held by a business. Typically this data is information that is high level and non-transactional, and therefore likely to be more stable, used more frequently, and most useful for reporting and informing future strategy. While different industries and individual companies may treat different data elements as master data, common examples of master data elements include basic information such as the name of a supplier/customer and product reference numbers.

Given the nature of master data, this information is often used across multiple platforms and software programs in a business. To avoid inconsistencies and confusion, it is important that the exact same identifiers are used for master data elements – whatever these identifiers are (numbers, letters, words, codes etc.). Good master data management therefore involves ensuring that there is a single central record of certain data elements (e.g. supplier name), which data is pulled directly from when used in transactions and messages etc. This way, when information needs to be changed, all that is required to ensure that the new, correct data is used across the business is for the master data element to be updated.

The problems with having poor master data and processes

Although every supply chain business depends on the successful exchange of data to/from partners, many do not have reliable master data lists. This can be caused by a number of factors, such as the existence of multiple data lists that need to be consolidated (common after mergers and acquisitions), or simply a lack of prioritisation of data management by IT teams. Similarly, some companies may have well-maintained master data lists, but lack the necessary processes to ensure that data is used correctly.

Whatever the reason behind a company experiencing issues with master data, however, the resultant issues are the same. These fall into three main categories:

1) Errors

First and foremost, the most apparent issue relating to poor or inconsistent master data is the increased capacity for errors. An incorrect address, for example, can lead to delays and frustration on both ends of a transaction as messages/orders do not reach the intended recipient. Similarly, erroneous item prices and account numbers can cause huge repercussions for the company and individuals at fault.

2) Reduced capacity for performance analysis

With poor data management, seemingly simple tasks, such as identifying which customers are most valuable to your business or which products are most popular, become difficult. Without the ability to pull reliable reports on B2B information and KPIs (key performance indicators), it becomes tricky to identify both how you are currently performing and what can be done to improve moving forward.

3) Inefficiency

With reliable data, data entry and data processing are fast and simple. Sadly this is not the case in businesses without good data processes. In businesses with messy data, automation is extremely difficult; information in individual transactions typically needs to be checked, interpreted and inputted manually if costly errors are to be avoided. Manual data processing is not a viable long term solution for growing businesses, however, as human errors are unavoidable – plus staffing costs will quickly eclipse the cost of investing in an automated system.

Master data: a crucial first step towards wider automation

Over recent decades automation has grown from being a “nice to have” to an essential part of modern supply chains. From internal system automation to the exchange of structured electronic messages between partners (known as electronic data interchange, or EDI), virtually every stage of the trading cycle can now be improved by intelligent technology. The pace of business today is such that manual processes are simply unable to compete in terms of efficiency and cost effectiveness

Without reliable master data it is difficult for any level of supply chain automation to be implemented. Think of your ideal, cost- and time-effective business processes as a house you want to build. In such a scenario your master data elements are the bricks. If they are inconsistent or poorly cast, this will have an impact on the stability of the whole structure.

As a result, for any supply business looking to move towards automation of any kind, taking the time to build a reliable master data list and accompanying processes is an important first step. Unfortunately, as building master data and conducting master data synchronisations can be time consuming, many businesses put these tasks off until they are absolutely necessary. When they then come to implement an EDI solution this leads to unnecessarily time-consuming migrations and customer onboardings.

Once I have sorted my master data – what next?

If you would like to find out more about what kind of automation it is possible once you have cleaned up your master data, why not read our article What is Electronic Data Interchange and What are the Benefits of EDI? If you would like to know more about what implementing an EDI system entails, you may also be interested in this article, where we explore this process in detail.

Alternatively, if you have any other questions regarding this topic or anything relating to B2B integration please do feel free to get in touch.

Der Beitrag What is Master Data and Why Does it Matter? erschien zuerst auf ecosio.

]]>Der Beitrag Three Tips to Help You Improve E-invoicing Processes erschien zuerst auf ecosio.

]]>The following are three key practical steps you can take to ensure e-invoicing processes are as successful as possible for your business.

1 – Have a clear plan in place

A recent study by MIT Sloan and Capgemini indicated that despite 90% of CEOs believing that the digital economy will affect their industry, just 15% of them have a digital strategy in place at all – let alone a strategy for e-invoicing processes. Unfortunately, most businesses are only prompted to act when required to by a large trading partner or new legislation. Unfortunately, the time pressure in such situations typically leads to a rushed decision-making process during which an ill-fitting or non-future-proof solution is opted for.

By taking the time to assess your company’s current and future e-invoicing and document exchange needs and developing a realistic plan, you are far more likely to end up with a successful solution and future-proof e-invoicing processes.

2 – Clean up master data

The accuracy and reliability of your business’s master data is crucial to successful automated document exchange. As a result, tidying up master data is always the first step when establishing a connection to trading partners.

Ensuring your master data is in order in advance of future partner onboardings (be they B2B or B2G) will streamline the process and help to ensure you can experience the benefits of a reliable connection sooner.

To learn more on what a master data synchronisation process involves and how it can benefit you, read our article “What is Master Data Synchronisation and Why is it Needed?” on this topic.

3 – Don’t try to do too much yourself!

Sadly a wealth of internal resources – particularly when it comes to IT – is a luxury very few businesses enjoy. Despite this, many organisations attempt to keep management of key B2B processes such as e-invoicing in-house. Unfortunately, however, for a successful outcome to be achieved, technical expertise is required during all parts of the connection process, from set-up to monitoring. When the need to stay on top of constantly changing regulations is factored in too, managing e-invoicing connections in-house becomes a daunting task – particularly for those with other responsibilities or without EDI experience.

An experienced and capable provider can simplify e-invoicing processes (and EDI processes more generally) hugely. As well as relieving pressure on internal teams, a good provider should be able to safeguard key business processes for the future too, by helping to establish, test and monitor connections.

Want more information?

This article is taken from a section in our white paper “E-invoicing in Europe: State of Play”. In this comprehensive white paper we look in detail at current e-invoicing regulations across Europe, Peppol, the future of e-invoicing and how to stay on top of changing requirements.

Download your free copy of “E-invoicing in Europe: State of Play”, simply submit your details.

Alternatively, if you have any questions about your particular situation or anything else EDI or e-invoicing related, feel free to get in touch! We are always happy to help!

Der Beitrag Three Tips to Help You Improve E-invoicing Processes erschien zuerst auf ecosio.

]]>Der Beitrag Electronic Data Interchange (EDI) with 3M erschien zuerst auf ecosio.

]]>Even if you have not heard about 3M in the past, it is quite likely that you stumbled upon one of their products in everyday life. One of their most famous products is, without doubt, the Post It note. In innovation classes, Post It notes are often taken as a famous example for a serendipity innovation. Originally in search for a super-strong adhesive, the chemist at 3M created a low-tack glue which allows for an easy attachment and detachment of the glued item. The rest is history.

Today 3M produces much more than just Post It notes. In order to allow for efficient management of its procurement and distribution processes, 3M makes heavy use of electronic data interchange (EDI). In the rest of the article we outline the most important facts in regard to EDI on the supplier’s side – that is, if your company delivers goods or services to 3M.

EDI with 3M

If you have been requested to start doing EDI with 3M, there are three important aspects to consider: document formats, exchange protocol and the onboarding process with 3M. We will further examine all three aspects in detail.

EDI document formats

On the supplier side 3M typically focuses on the following EDI document types:

- ORDERS (Purchase Order)

- ORDCHG (Purchase Order Change)

- ORDRSP (Purchase Order Response)

- DESADV (Despatch Advice)

- INVOIC (Invoice)

Thereby, they support the following EDI document formats:

- EDIFACT D96A

- ANSI ASC X12 version 4010

The exact format specifications may be retrieved as follows.

- Go to: https://www.3m.com

- Select your preferred Location/Language

- Select menu options > Suppliers > Source to Pay Transactions > Electronic Data Interchange

- Download the required document

Unless your ERP system is able to directly import and export the EDI formats mentioned above (which is unlikely), you have to employ a converter solution. The converter solution translates between the document format of your ERP system and the EDI format of 3M and vice versa. Usually converter solutions come either as an on-premise solution, or are provided by a service provider as a managed solution.

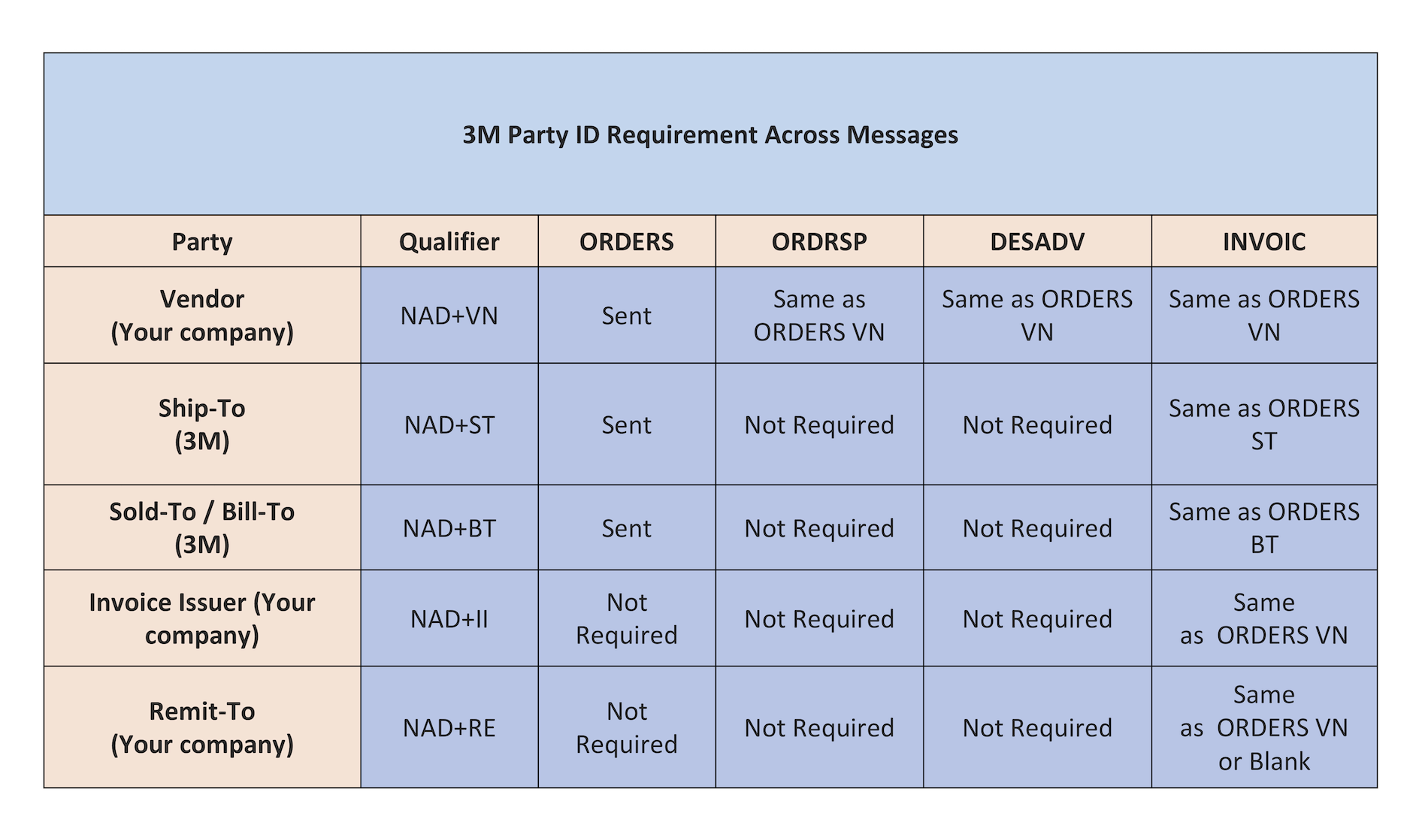

Of particular importance in regard to the document formats is the turnaround of information from 3M to your ERP and back to 3M. To be more precise – several identifiers have to be taken from the ORDERS message, which is received from 3M and must be returned in the documents which are being sent back to 3M (ORDRSP, DESADV and INVOIC). When using EDIFACT, the following turnaround principle applies.

3M Party ID Requirement Across Messages

It is, for instance, essential, that the NAD+VN information from the ORDERS is correctly returned in the ORDRSP, DESADV and INVOIC message. The most complex document type is the INVOIC message. All NAD identifiers from the original ORDERS must be correctly returned in the INVOIC message.

Thus, it is imperative that the correct turnaround process is configured in the ERP system, ensuring that all information from the ORDERS is stored in the ERP and correctly returned when the INVOIC is exported.

When working for instance with an SAP ERP system, the correct configuration of the EDPAR table helps transfer the identifiers from the ORDERS through the ERP and back to the INVOIC document.

EDI exchange protocol

To allow for an exchange of EDI documents with 3M, an exchange channel using an EDI protocol must be set up. An EDI service provider like ecosio can take care of this connection for you and create a connection to 3M’s EDI service provider in order to exchange the required EDI messages. Exact details of the provider will be communicated to you by 3M during the course of the project.

3M along with their EDI service provider will set up two connections: a test connection and a productive connection. The test connection will be used during the onboarding phase to exchange documents with the test system of 3M.

The production connection is then used after the go live.

EDI onboarding process

The EDI team of 3M together with your own EDI service provider will assist you in setting up the EDI process to 3M.

First, master data has to be aligned to avoid disconnects relating to units of measurement and price multipliers. The necessary EDI document mappings should then be set up, after which 3M will provide you with EDI test orders via the test connection. You are then required to send back the necessary order response, despatch advice and invoice documents. Thereby, 3M’s onboarding team will execute various test cases, covering the different aspects of your business relationship to 3M, e.g., different types of deliveries.

After the test phase has been completed successfully, your EDI process will be put into production and your company will start to exchange EDI messages with 3M.

How ecosio can help

Ecosio is experienced in connecting suppliers to 3M and recently connected Mitsubishi Polyester to the conglomerate.

Our unique Integration Hub supports all secure EDI protocols and formats, meaning one connection to ecosio allows message trading with 3M (and other partners) in the correct format and over the correct protocol with minimum effort.

Unlike other providers, ecosio offers an integrated, managed solution which is embedded directly in the user’s ERP system as a native feature. As a result, important processes are built into the existing user interface, producing useful end-to-end message visibility.

Benefits at a glance

- All testing, mapping and routing achieved via a single connection to ecosio’s cloud-based EDI solution (our Integration Hub)

- No internal EDI knowledge needed

- Hassle-free partner onboarding

- Unparalleled end-to-end data visibility thanks to deep ERP integration

Any questions?

If you still have questions, feel free to contact us. We would love to help you!

SAP ERP and SAP S/4HANA are the trademarks or registered trademarks of SAP SE or its affiliates in Germany and in several other countries.

Der Beitrag Electronic Data Interchange (EDI) with 3M erschien zuerst auf ecosio.

]]>