Der Beitrag What is Web EDI? erschien zuerst auf ecosio.

]]>Video transcript:

What is Web EDI?

Web EDI is a tool for connecting to suppliers that lack the infrastructure to conduct electronic data interchange (or EDI) in the traditional manner.

In addition to enabling your suppliers to read the EDI messages you send to them, Web EDI allows suppliers to create follow-up documents and return them to you. Web EDI thus enables businesses to extend automation across more of their supply chain.

For your smaller partners it allows simple transmission of EDI documents via a web portal.

For you, meanwhile, deep integration with your ERP system ensures that message exchange via Web EDI looks no different to that via classic EDI.

Why is Web EDI needed?

Generally speaking, a supply chain business’s suppliers can be divided into two distinct groups: larger suppliers and smaller suppliers.

- Larger suppliers: Larger suppliers are typically already able to do classic EDI. All that’s required to start exchanging EDI messages with them is for a message implementation guide to be exchanged and mapping and routing to be completed.

- Smaller suppliers: Smaller suppliers on the other hand generally don’t have the ability to conduct EDI and are only able to trade automated messages if their partner provides access to a Web EDI portal.

Although each smaller supplier may not seem significant, when added together, smaller suppliers often constitute a substantial proportion of a business’s partner network (this is referred to as “the long tail”). Communication with smaller partners also typically requires a huge amount of time and effort from internal teams to ensure everything is processed correctly.

An efficient EDI solution should aim for total automation of supply chain communication and should thus cater for both types of supplier. As Web EDI offers the only way to achieve automated exchange of structured documents with partners lacking EDI capability, it is therefore an essential part of a successful EDI solution.

What does using a Web EDI system involve?

So what does using a Web EDI system involve? To answer this let’s examine your perspective and that of a partner using your Web EDI portal.

From your perspective

As far as your ERP system is concerned, once smaller partners have been provided with access to your Web EDI portal, there is no difference between the messages received via Web EDI and those received from larger partners via traditional EDI. All B2B message exchange is automated, with all incoming messages arriving directly into your ERP and all outgoing messages sent directly from your ERP. Essentially no additional work is required (assuming your EDI provider takes care of updates and monitoring).

From your supplier’s perspective

For your suppliers the experience involves slightly more input. First they will be provided with a login to your own tailored portal, within which access rights and alerts can be set as desired.

When an incoming message is received, the supplier is alerted via email to make sure it isn’t missed. The structured data in the EDI message is converted into a human readable format and can be downloaded as PDF. This can then be filed/stored by the supplier as desired.

When sending messages via the portal no EDI knowledge is required either. All the supplier needs to do is enter the relevant information and click send. The portal converts the data into the agreed format and delivers it to your ERP.

Outgoing messages can even be semi-automatically filled with pre-populated information, based on incoming messages. For example, to send an order response the supplier may not need to manually enter any information, as the data will be pulled directly from the incoming order. This process is also known as a “PO flip”.

In the best systems your ERP and Web EDI platform will always be in sync, meaning suppliers will be able to see any order changes in real time. In such systems it may even be possible for individual order changes to be merged automatically.

For example, let’s say you ordered 4 crates of bananas from your supplier initially, but then subsequently wanted to amend this order to cancel one crate of bananas and add a crate of apples.

In a modern system your changes would update the original order in the Web EDI portal directly and notify your supplier instantly.

In addition to reducing the likelihood of you experiencing order issues, the combination of real time synchronisation and automatic data merging makes life much easier for your suppliers.

The benefits of Web EDI

In summary, Web EDI provides several benefits for both suppliers and customers.

For customers the main benefits are…

- A more streamlined partner network

- Cost and time savings through increased automation

- …and reduced pressure on in-house teams

For ecosio customers these benefits are also bolstered by 24/7 platform monitoring, automatic updates and unparalleled data visibility thanks to deep ERP integration.

For suppliers, the benefits include…

- Semi-automated creation of key B2B documents

- The ability to trade with larger partners

- … and access to real-time purchase order information and purchase order changes (in ecosio’s system all order changes can also be merged automatically)

Find out more

At ecosio we are experts when it comes to Web EDI and efficient, automated partner connections. Please click here, if you would like to learn more about our unique ecosio’s Web EDI Solution, or discover more about our updated product, ecosio.flow.

Alternatively, feel free to contact us. We’ll be more than happy to help you experience the benefits of Web EDI and are always happy to answer any questions you may have!

Der Beitrag What is Web EDI? erschien zuerst auf ecosio.

]]>Der Beitrag Three Challenges for Web EDI Solutions erschien zuerst auf ecosio.

]]>However, underneath this overarching requirement are three key challenges that successful Web EDI solutions must overcome to provide maximum benefit to customers…

[Need a reminder of the basics of Web EDI first? Check out our video on this topic!]

1) Providing access to real-time information for everyone

In order for a partner connection to function at maximum efficiency, suppliers must have access to up-to-date purchase order information, including purchase order changes (e.g. resulting from a shift in demand from the end customer). Suppliers should also be given the opportunity to send electronic purchase order responses as well as dispatch advices and invoices. Compared to traditional paper-based exchange processes, such a system produces vastly improved data visibility for all parties.

With ecosio’s solution purchase order changes are automatically reconciled with the original purchase order. Thus, the supplier always has the most recent information at hand.

2) Minimising partner effort

Although most businesses’ main concern when investing in a Web EDI solution is minimising manual effort on their own end, it is also important that the portal is as useful as possible for your partners, as this will result in better takeup.

By semi-automatically generating purchase order responses, dispatch advices and invoices where possible, the likelihood of errors being introduced through manual input is virtually eliminated.

ecosio’s Web EDI solution aims to reuse as much information as possible from the original purchase order to maximise efficiency. Consequently, a purchase order response may be created based on the data from the underlying purchase order; a dispatch advice may be created from the data from the underlying purchase order or the purchase order response; and an invoice may be created from the underlying despatch advice (or from the purchase order if no despatch advice is being used). Meanwhile ecosio’s sleek and clean user interface allows for easy data processing.

3) Flexibility of Web EDI solutions

The third key challenge for Web EDI solutions is flexibility. For example, if a supplier using your Web EDI wants to switch to classic EDI your solution should be able to cope. Similarly, if new document types (e.g. DELFOR for delivery forecasts) are required, integration of these should be possible.

You may also want to bolster your solution moving forward by adding Supplier Relationship Management (SRM) features such as audit management or supplier self-assessment modules. This is made much simpler if you have an EDI solution that can grow as your needs evolve.

ecosio’s Web EDI solution is capable of being supplemented by many key SRM features – each of which can be purchased and combined in modular fashion as required. This means that no matter how much your requirements change over time, your solution can be adapted accordingly, ensuring it stays as efficient and valuable to your business as possible.

Want more information?

This article is taken from our white paper “Can Web EDI Really Transform My Supply Chain?”. In this white paper we also explore the benefits of Web EDI, how partners are connected, what a good system includes, and the importance of considering future needs. For those interested in seeing what a Web EDI system looks like in practice, we also provide a breakdown of a typical action including screenshots.

Download your free copy of “Can Web EDI Transform My Supply Chain?”, simply enter your details.

Or click to discover more about our updated product, ecosio.flow.

Alternatively, if you have any questions about your particular situation or anything else EDI related, please do not hesitate to get in touch! We are always happy to help however we can.

Der Beitrag Three Challenges for Web EDI Solutions erschien zuerst auf ecosio.

]]>Der Beitrag Supplier Relationship Management – 6 Tips for Retail Businesses erschien zuerst auf ecosio.

]]>For no industry is this truer than for retail. Whilst retail has always been an intensely competitive marketplace, new pressures have been added thanks to the recent shift in customers’ behaviour and expectations, particularly regarding ease of ordering and delivery speed. As well as expecting to receive items within one or two days, consumers increasingly rely on efficient returns as more and more people over-order to try on at home. What’s more, it has never been easier or more impactful for customers to write a negative review if they experience issues regarding an order.

For years retail supply chains were optimised for high-street stores, with online sales considered a subsidiary stream. Consequently, many retail supply chains today suffer from legacy issues related to inefficient logistics processes and poor cross-channel coordination as they struggle to adapt their processes to enable them to meet current demands whilst simultaneously preparing them for the future.

In this article we explore six key things you can do to improve the efficiency of your retail supply chain:

1 – Set out your plan

It may sound simple, but writing down your objectives and how you aim to achieve them is always the most effective starting point. However you seek to tackle the issues you’ve identified, be it through updating your distribution strategy, staff training, outsourcing logistics processes or an increased focus on supplier relationship management (SRM), creating a clear and detailed plan will help to ensure that you are constantly moving towards the outcome you want.

2 – Automate, automate, automate!

Changing logistics and data processes can seem like a daunting task, which is why so many retail supply chain businesses retain outdated systems and struggle to process in an effective manner the numerous different message types (sent via various protocols) received daily from partners. Yet handled correctly, not only is process automation a simple process, it is one which can transform your business.

Key benefits of effective process automation include:

- Time and cost-saving – Arguably the most easily identifiable benefit of automating data exchange, logistics and procurement processes is the time (and resultant money) it can save, from elimination of manual data tasks, to quick and easy data monitoring, in turn enabling easy identification of further areas for process improvement.

- Accuracy and reduction in human error – With a streamlined electronic data interchange (EDI) system in place human errors are all but eliminated, resulting in reliable information exchange and dependable output.

- Collection of useful data – In addition to ensuring the accuracy of the data being exchanged between you and your partners, an efficient B2B integration system can provide useful analytics relating to information such as orders, inventory levels and supplier performance.

In short, as we move towards e-procurement or electronic buying processes, retaining a non-automated system (no matter how attractive that option may seem now) will become increasingly untenable, especially in the fast-moving world of retail. The faster you seek to automate key business processes, the less chance you have of being left behind!

3 – Improve supplier relationships

Healthy supplier relationships form the backbone of a successful retail supply chain. The best relationships are not simply transactional connections, but more like alliances. By enhancing your B2B integration you can boost supplier relationship management through accurate data forecasting, automated deadline reminders and improved workflows, in turn relieving procurement teams and minimising costly errors and oversights.

Help your suppliers to help you!

With a future-proof electronic data interchange (EDI) system in place not only will you and your partners be speaking the same data language, the resulting improvement in supply chain visibility will allow them to see key inventory information, ensuring they are better positioned to fill future orders. Thanks to web-based EDI portals, today even partners who don’t currently have an EDI system can be connected to enable these advantages across your entire network.

4 – Monitor supplier performance

As we’ve already established, good supplier relationship management is key to retail supply chain success. In addition to improving the efficiency of your supplier relationships by streamlining data transfer, implementing an efficient B2B integration system can also provide access to easy-to-digest information regarding supplier performance. With quick access to key performance indicators (KPIs) such as partners’ fill rates and order accuracy, identification of areas for improvement becomes simple. In addition, you may want, if possible, to set targets for your partners to make sure they are aware of what is expected of them and allow both parties to track task progress. Ideally, performance can then be tracked directly through your B2B integration hub via supplier audits and quality management reports.

5 – Maintain data transparency

Unfortunately, no matter how streamlined your supplier relationship management processes are, things will inevitably go wrong from time to time, be it a delayed shipment or a misjudged demand. What’s important when this happens is to catch the issue quickly and identify where things went wrong so as to ensure that it doesn’t happen again. When it comes to data exchange processes, maintaining transparency in the form of full-text searchability across all documents and messages is extremely valuable and allows for issues to be spotted before they can escalate.

6 – Don’t try to do it all yourself!

Just because you know your business better than anyone else, it doesn’t mean you are best placed to implement, manage and monitor day-to-day data processes. The in-house resources required to ensure the success of commerce-critical data exchange can be significant. Plus the difficulty of in-house teams staying on top of day-to-day data routing and mapping tasks alone often means that little to no time is devoted to process improvement and future-proofing key business processes – something that is key in an industry as competitive and dynamic as retail.

By moving to a future-forward, managed EDI service the ongoing hassle of managing logistics and procurement processes is removed. Further, this enhanced B2B integration can also be accompanied by SRM capabilities such as delivery performance and audit management modules, with in-house resources in turn redirected to forward-thinking process improvement.

Find out more

For more information about supplier relationship management and how digitisation of supplier processes could help streamline your supply chain, visit our page “Supplier activation“.

Alternatively, if you have questions about your specific situation please contact us or use our chat – we are happy to help!

Der Beitrag Supplier Relationship Management – 6 Tips for Retail Businesses erschien zuerst auf ecosio.

]]>Der Beitrag What is a Tier supplier? erschien zuerst auf ecosio.

]]>- Suppliers are categorised as Tier 1, Tier 2, Tier 3, Tier-n based on their distance from the OEM, reflecting the sub-supplier structure

- In the automotive industry, OEMs source modules from specialist suppliers, who assemble components from other suppliers, with individual parts supplied on the third tier

- Close links between OEMs and tier suppliers require fast and effective communication of required quantities to ensure the supply of modules, components and parts, particularly in just-in-time and just-in-sequence processes, supported by electronic data interchange

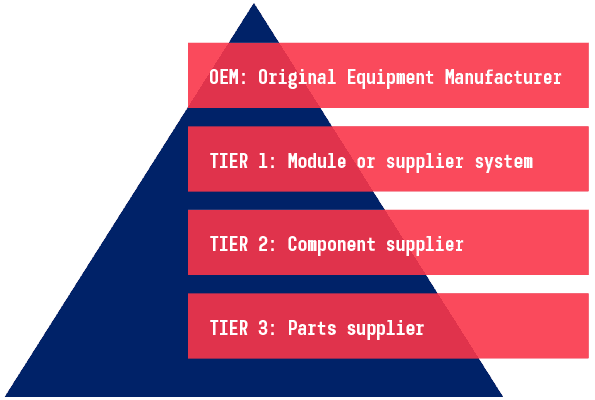

Structure of a supply pyramid

A supply pyramid describes the structure of a supply chain with the end product producer at the top. The end product producer is referred to as an OEM, which stands for Original Equipment Manufacturer. The suppliers of modules and systems are directly underneath the OEM. These suppliers are supplied by component suppliers who in turn buy their goods from parts suppliers.

Suppliers are referred to as Tier 1, Tier 2, Tier 3, Tier-n suppliers, depending on their distance from the OEM. This reflects the sub-supplier structure.

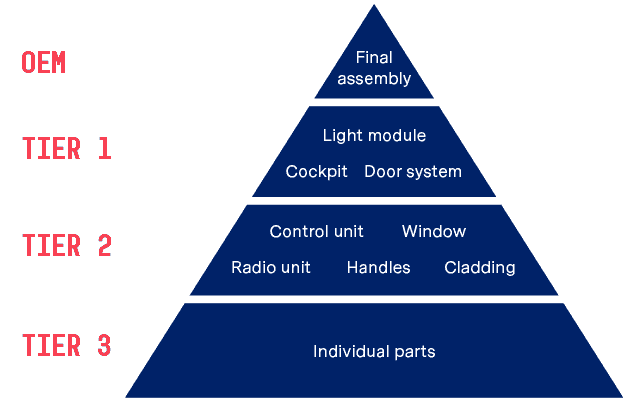

Tier supplier structure visualised – an example from the automotive industry

The automotive industry is characterized by complex and closely interlocked logistics chains. Instead of producing all their components in-house, automotive manufacturers procure the individual modules from specialist suppliers. These suppliers will in turn assemble components supplied by specialised component suppliers. The suppliers of individual parts are found on the third tier.

These boundaries are not always so clearly defined. A supplier may thus be both Tier 1 and Tier 2 – for example a business might deliver antenna modules to both OEMs and Tier 1 suppliers.

The following diagram illustrates an example of an automobile supply chain:

Supply pyramid in the automotive industry

Challenges along the supply chain

Close links between OEMs and their individual tier suppliers pose special challenges to smooth process operation. The horizontal integration of many different suppliers and their own suppliers will, for instance, demand that required quantities are communicated fast and effectively if the supply of modules, components and individual parts is to be ensured. This is a critical factor in success especially with just-in-time and just-in-sequence processes. Electronic data interchange is used to ensure communication, whilst the concepts of delivery schedule and just-in-time deliveries may for instance be deployed. Standardisation organizations such as ODETTE and VDA have already developed many useful standards to allow efficient operation of automobile supply processes.

Apart from logistics messages such as delivery schedule, despatch advice, etc., continuous digital engineering is essential. This will, for instance, include the exchange of construction data such as CAD (Computer-aided design) drawings and the like.

Any questions?

If you have questions about logistics in the automotive industry or would like to learn more about implementing an EDI based process please contact us – we look forward to hearing from you!

You can also find more useful information on this and other relevant topics in our extensive resource centre and blog.

Der Beitrag What is a Tier supplier? erschien zuerst auf ecosio.

]]>