Der Beitrag What are DUNS Numbers? erschien zuerst auf ecosio.

]]>DUNS numbers were introduced by the company Dun & Bradstreet in 1962. Dun & Bradstreet, whose head office is in New Jersey, USA, is currently the largest provider of business information about companies in the world.

A Screenshot of the Dun & Bradstreet Website

Worldwide there are regional companies, who offer company data and ratings about customers, suppliers and potential business partners to their clients. This data contains information about branches, the number of employees, turnover, etc… and information to payment behaviour. This is all shown through a score, which predicts a specific reliability and financial stability.

In order to enter this information into the database accurately, the DUNS number was created in 1962 (the correct name is D&B D-U-N-S® number). This number is unique worldwide and does not overlap with any other number.

Today, DUNS numbers are not only used by many companies, but also by the United Nations, the European Union, the American National Standard Institute (ANSI) and even the American government, to name the most well known establishments.

In the United Kingdom, DUNS numbers are used mostly in the industry sector and related companies, such as the automotive or chemical industry. It is also reflected in the EDI standards that were developed by the corresponding industry associations, for instance ODETTE and their respective EDIFACT standards.

How to apply for a DUNS number

As mentioned above, Dun & Bradstreet have an abundance of local companies, which look after the national clients. In the UK, this company is Dun & Bradstreet UK.

The single purpose of a DUNS Number is to identify companies and lenders. These are e.g. company divisions, branches, but also public institutions, tradesmen and other self-employed persons. DUNS numbers cannot be given to private persons.

Companies can apply for a DUNS Number free of charge on the Dun and Bradstreet platform for the UK. The processing time for the creation of a DUNS number in the UK is five working days. Before they can create your DUNS number, Dun & Bradstreet need to thoroughly check the entered data about the company, hence the processing time.

Structure of DUNS numbers

A DUNS number is composed of 9 digits and is unique worldwide, therefore it does not overlap with any other DUNS number. Even when a company discontinues trading activities (bankruptcy, merging with another company, etc.), their DUNS number will not be reused. This is guaranteed by Dun & Bradstreet central distribution in their distribution policies.

Die DUNS®-Nummer der ecosio InterCom GmbH lautet beispielsweise: 341301537

Who does a DUNS number belong to?

If you need to find out to which company a given DUNS number belongs to, you can also use the Dun & Bradstreet UK platform.

A Screenshot of the Dun & Bradstreet UK Platform

You just need to enter the DUNS® number to search for the company it belongs to. Alternatively, you can also look for the DUNS number of a company by entering the company name and address.

Do you have any questions?

Do you still have questions about DUNS numbers or electronic data interchange? Feel free to contact us, we would love to help you!

Der Beitrag What are DUNS Numbers? erschien zuerst auf ecosio.

]]>Der Beitrag Electronic Data Interchange (EDI) with the Help of VDA Standards erschien zuerst auf ecosio.

]]>The Association of the Automotive Industry was founded in 1901 and is an interest group of the German automotive industry and its suppliers. The headquarters are located in Berlin.

VDA Headquarters in Berlin (Source: Wikimedia Commons

The VDA is publicly known through the Internationale Automobilausstellung (IAA, International Automotive Exhibition), since they operate as their organiser. In addition to the representation of interests, VDA also undertakes standardisation tasks, with recommendations for logistical processes in the automotive sector to be adopted. Those recommendations established themselves throughout the years as the de facto standard of the German automotive industry.

The development of the VDA standards

Already in 1977, before even UN/CEFACT started to develop the EDIFACT standards, the Verband der deutschen Automobilindustrie began, defining EDI message standards, which were dedicated to the automotive industry and its suppliers. In contrast to EDIFACT or ANSI ASC X12, no segments or separators are used, but instead elements with constant length, called the fixed length format are used. Every data element has a defined length, within which the information can be transmitted. If the information is shorter than the defined length, the rest is filled out with blank spaces.

Numbering of the VDA messages

Each VDA message type has a unique number, almost like a description. Message type 4905 describes for example a delivery forecast. At the end of this article you will find a list of the different VDA standards.

Current development

The current fixed length VDA standards are gradually being replaced by EDIFACT document types. Therefore, the VDA association releases recommendations, on how EDIFACT messages can represent VDA document types. Nevertheless, the current VDA message types are still very frequently used in the automotive industry and one can expect this to still be the case in the coming years.

How are VDA standards being used?

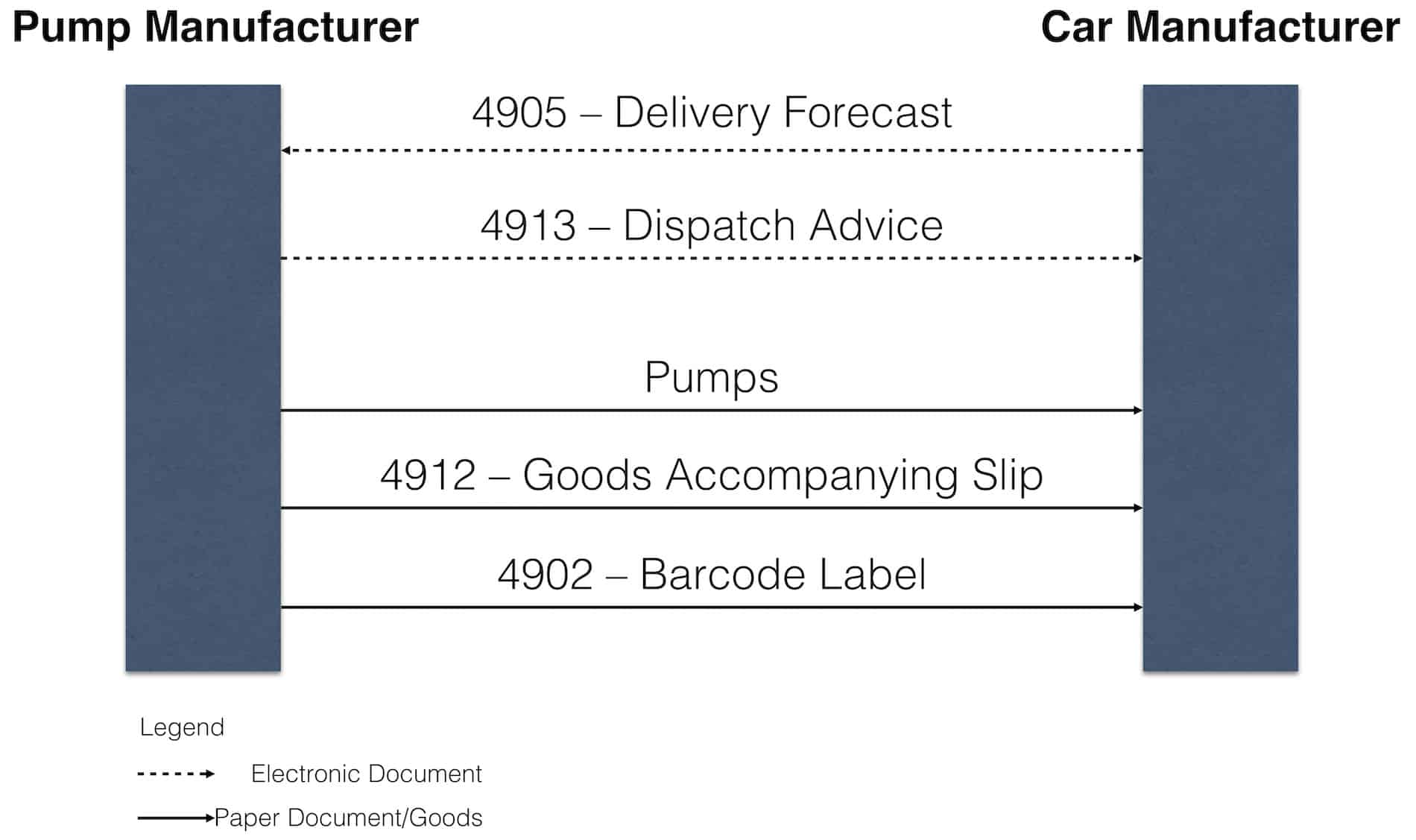

Depending on the car manufacturer, different VDA standards can be used. The following scenario, depicted with a delivery forecast and despatch advice, as well as the paper documents which go with it, come up very frequently. This example is of a pump manufacturer, who sends goods to a car manufacturer.

An Example of the Use of VDA Standards

The car manufacturer forecasts the deliveries to the pump manufacturer with the help of a 4905 message. The pump manufacturer prepares the goods accordingly and confirms the delivery with a 4913 message. Next step is to ship the pumps, together with two paper documents: a barcode label 4902 together with the goods, which can be scanned with a barcode scanner and a paper-based goods slip 4912.

Are you looking to use VDA standards?

The use of VDA standards is now required by more and more car manufacturers and their pre-suppliers. However, the implementation of the corresponding electronic document types and the paper documents which go with it, including the correct barcodes, is not so simple. We are more than happy to help you with any questions you might have about VDA.

List of VDA standards

The list below gives you a (non-exhaustive) overview of the important standards, which the VDA association adopted (as of February 2015).

| Nr. | Description | First Publication |

|---|---|---|

| 4900 | Transmission of ODETTE messages; EDIFACT payload | Jan 91 |

| 4901 | Enquiries/offer | Oct 77 |

| 4902 | Transport label (barcode enabled) | Sep 94 |

| 4903 | Microfilm | Apr 82 |

| 4904 | Delivery forecast | May 83 |

| 4905 | Transmission of call off | Apr 96 |

| 4905/2 | Transmission of call off based on ODETTE-DELINS Version 3 | Jan 91 |

| 4907 | Transmission of remittance advice | Aug 93 |

| 4911 | Transmission of price data | Jan 89 |

| 4912 | DFÜ goods slip | Jan 91 |

| 4913 | Transmission of delivery notes and transport data | Mar 96 |

| 4914 | File Transfer Protocol (FTP) – contains 4914/1 and 4914/2 | Mar 88 |

| 4915 | Transmission of detailed call off (JIT) | Apr 96 |

| 4916 | Transmission of call off just-in-sequence | May 91 |

| 4918 | Transmission of vehicle identification and transport data | Apr 87 |

| 4919 | Transmission of vehicle arrival and departure notification; process description | Apr 87 |

| 4920 | Transmission of forwarding instructions (sender/supplier to shipper) | Apr 89 |

| 4921 | Transmission of delivery data (shipper to client/goods receiver) | Apr 89 |

| 4922 | Form for the shipment of goods between the supplier, shipper and client – shipping request | Jun 10 |

| 4923 | Transmission of enquiries | Jan 92 |

| 4924 | Transmission of offer/quotation | Jan 92 |

| 4926 | Transmission of acknowledgment of order | Sep 93 |

| 4927 | Transmission of equipment statement and equipment movement | Feb 97 |

| 4928 | Checklist for production partners (system suppliers) with just in time delivery in the information processing area; first publication | Aug 96 |

| 4929 | AVIEXP: EDI for delivery notes and transport data; VDA guideline of the ODETTE subset AVIEXP V5R1 for UN/EDIFACT message DESADV D96A | Feb 98 |

| 4930 | Transmission of inventory and stock movement information with external warehousing | Apr 93 |

| 4931 | Packaging data sheet | Apr 93 |

| 4932 | INVOIC: EDI for invoices and credit notes data; VDA recommendation to ODETTE subset V5R1 for UN/EDIFACT message INVOIC D97A | May 99 |

| 4933 | Standardised transport note/ shipping readiness advice (including labels) | Jul 14 |

| 4936 | Web EDI (part I) for the deployment of call off data, the logging and shipment of delivery notes (shipment, transport and delivery slip data), printing of the goods slip, and deployment of the credit note data. | Nov 01 |

| 4937 | Automated responses for delivery notes part 0: process description and general information | Mar 09 |

| 4937 P1 | Automated responses for delivery notes part 1: syntax and service report (EDIFACT CONTRL) | Mar 09 |

| 4937 P2 | Automated responses for delivery notes part 2: application error and confirmation message (EDIFACT APERAK) | Mar 09 |

| 4937 P3 | Automated responses for delivery notes part 3: receiving advice notice (EDIFACT RECADV) | Mar 09 |

| 4938 P1 | Process framework for the exchange of electronic invoices with the use of EDIFACT without digital signature | Apr 12 |

| 4938 P2 | Global INVOIC application manual – data structure (incl. labels) | Jun 14 |

| 4938 P3 | Electronic invoicing process with small and medium sized businesses in the automotive industry (incl. labels) | Dec 13 |

| 4938 P4 | Freight invoice – data structure for the exchange of invoice data for transport services. | Dec 13 |

| 4939 | Transport and shipping slips | Dec 07 |

| 4940 | Checklist for the deployment of ODETTE messages | Aug 93 |

| 4941-1 | Part 1: Packaging account overview | Feb 06 |

| 4941-2 | Part 2: Packaging inventory report | Feb 06 |

| 4941-3 | Part 3: Packaging inventory discrepancy | Feb 06 |

| 4942-4 | Part 4: Packaging inventory correction | Feb 06 |

| 4942-5 | Part 5: Packaging inventory delimitation | Feb 06 |

| 4943 | Packaging batch report | Feb 06 |

| 4944 | Packaging transport request | Feb 06 |

| 4945 | Packaging transport status | Feb 06 |

| 4946 | Packaging request acknowledgment | Feb 06 |

| 4947 P1 | Part 1: Packaging movement notice | Feb 06 |

| 4947 P2 | Part 2: Packaging receiving confirmation | Feb 06 |

| 4948 P0 | Bypass/drop ship part 0: Process description and general information | Oct 06 |

| 4948 P1 | Bypass/drop ship part 1: order | Oct 06 |

| 4948 P2 | Bypass/drop ship part 2: order response | Oct 06 |

| 4948 P3 | Bypass/drop ship part 3: delivery notice | Oct 06 |

| 4949 | Proposition about the standardisation of the communication for the exception handling of the supply chain in aftermarket | May 07 |

| 4970 | Transport preview for finished vehicles | Jun 99 |

| 4971 | Pick up order for finished vehicles | Mar 00 |

| 4972 | Dispatch notice from plant/base for finished vehicles | Mar 00 |

| 4973 | Vehicle entry for finished vehicles | Mar 00 |

| 4974 | Vehicle exit for finished vehicles | Mar 00 |

| 4975 | Change/information notice for finished vehicles | Feb 00 |

| 4976 | Change/information confirmation for finished vehicles | Mar 00 |

| 4977 | Damage report for finished vehicles | Mar 00 |

| 4978 | Repair start/end notice for finished vehicles | Mar 00 |

| 4979 | Shipping readiness notice for finished vehicles | Mar 00 |

| 4980 | Loading instructions for finished vehicles | Mar 00 |

| 4981 | Usage of portal agents in the portal applications of the automotive industry | Oct 11 |

| 4982 | Data exchange between the companies of the automotive industry and the logistic service providers to fulfil the requirements of the import control system ICS of the European Union. | Dec 11 |

| 4983 | Transmission of attachments and signatures with EDIFACT messages (including labels) | Mar 12 |

| 4984 | Transmission of delivery forecasts (incl. labels) | Jun 14 |

| 4985 | Transmission of JIT call offs (incl. labels) | Jan 13 |

| 4986 | Transmission of production synchronous (JIS) call offs | Jun 14 |

| 4987 | Transmission of delivery notes (incl. labels) | Jul 14 |

| 4988 | Transmission of remittance advice with EDI (incl. labels) | Dec 13 |

| 4989 | Transmission of arrival confirmation | Dec 13 |

| 4990 | Inventory and stock movement report | Feb 15 |

| 4991 | Transmission of shipping notes (incl. labels) | Apr 14 |

| 4993 | Activity fields for portal managers | Feb 15 |

| 4999 | Glossary | Mar 15 |

Questions?

Electronic Data Interchange (EDI) with the Help of VDA Standards? Feel free to contact us, we would love to help you!

Der Beitrag Electronic Data Interchange (EDI) with the Help of VDA Standards erschien zuerst auf ecosio.

]]>Der Beitrag What is a Tier supplier? erschien zuerst auf ecosio.

]]>- Suppliers are categorised as Tier 1, Tier 2, Tier 3, Tier-n based on their distance from the OEM, reflecting the sub-supplier structure

- In the automotive industry, OEMs source modules from specialist suppliers, who assemble components from other suppliers, with individual parts supplied on the third tier

- Close links between OEMs and tier suppliers require fast and effective communication of required quantities to ensure the supply of modules, components and parts, particularly in just-in-time and just-in-sequence processes, supported by electronic data interchange

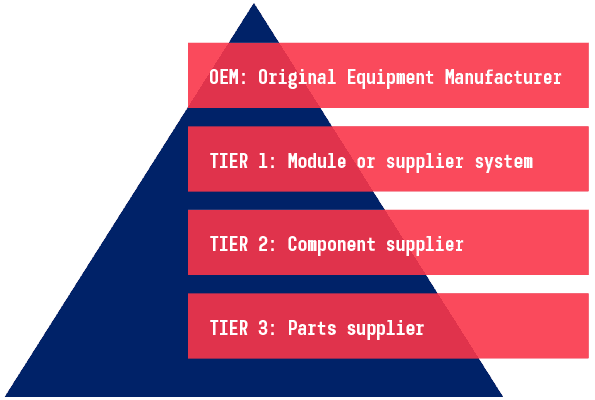

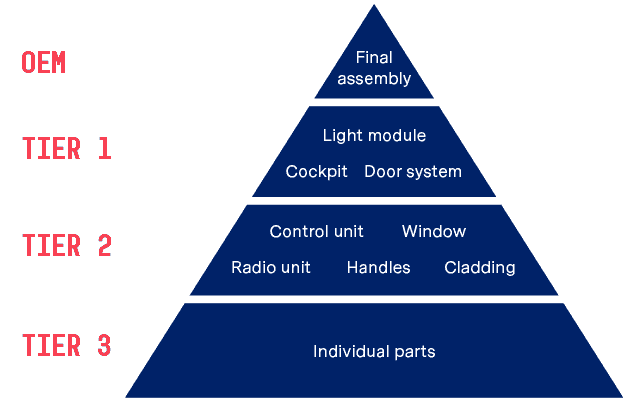

Structure of a supply pyramid

A supply pyramid describes the structure of a supply chain with the end product producer at the top. The end product producer is referred to as an OEM, which stands for Original Equipment Manufacturer. The suppliers of modules and systems are directly underneath the OEM. These suppliers are supplied by component suppliers who in turn buy their goods from parts suppliers.

Suppliers are referred to as Tier 1, Tier 2, Tier 3, Tier-n suppliers, depending on their distance from the OEM. This reflects the sub-supplier structure.

Tier supplier structure visualised – an example from the automotive industry

The automotive industry is characterized by complex and closely interlocked logistics chains. Instead of producing all their components in-house, automotive manufacturers procure the individual modules from specialist suppliers. These suppliers will in turn assemble components supplied by specialised component suppliers. The suppliers of individual parts are found on the third tier.

These boundaries are not always so clearly defined. A supplier may thus be both Tier 1 and Tier 2 – for example a business might deliver antenna modules to both OEMs and Tier 1 suppliers.

The following diagram illustrates an example of an automobile supply chain:

Supply pyramid in the automotive industry

Challenges along the supply chain

Close links between OEMs and their individual tier suppliers pose special challenges to smooth process operation. The horizontal integration of many different suppliers and their own suppliers will, for instance, demand that required quantities are communicated fast and effectively if the supply of modules, components and individual parts is to be ensured. This is a critical factor in success especially with just-in-time and just-in-sequence processes. Electronic data interchange is used to ensure communication, whilst the concepts of delivery schedule and just-in-time deliveries may for instance be deployed. Standardisation organizations such as ODETTE and VDA have already developed many useful standards to allow efficient operation of automobile supply processes.

Apart from logistics messages such as delivery schedule, despatch advice, etc., continuous digital engineering is essential. This will, for instance, include the exchange of construction data such as CAD (Computer-aided design) drawings and the like.

Any questions?

If you have questions about logistics in the automotive industry or would like to learn more about implementing an EDI based process please contact us – we look forward to hearing from you!

You can also find more useful information on this and other relevant topics in our extensive resource centre and blog.

Der Beitrag What is a Tier supplier? erschien zuerst auf ecosio.

]]>