Der Beitrag Value Added Network (VAN) – Key Questions Answered erschien zuerst auf ecosio.

]]>An EDI VAN, or Value Added Network is a closed-circuit network to which companies can be connected, and over which EDI data is exchanged via different protocols. To communicate with a company using a VAN, you generally require a VAN of your own. As we shall cover, however, this does not have to be something you manage in-house – and indeed shouldn’t be unless you have sufficient in-house expertise.

The three different ways to exchange EDI messages

Historically, there are three ways you can exchange EDI messages with trading partners…

- One-to-one connections

- Many-to-many connections

- One-to-many connections

One-to-one connections

One-to-one connections (also known as point-to-point connections) are custom-built to transfer messages independently and exclusively to each partner, as illustrated in the image below:

One-to-one connections require technical expertise to build as each connection is bespoke. For growing businesses or large enterprises it doesn’t make sense to build custom connections this way, as it is time-consuming and will overburden in-house resources, who may not have sufficient expertise in the first place. Outsourcing professional services to a third-party IT services company to build the connections for you may not be the lesser evil either, since you have to ensure governance, monitoring, maintenance, updates and other changes, which may lead to further complications when scaling.

As automation becomes an increasingly integral part of supply chain communications, the requirements for B2B connections are also growing. Businesses are now demanding analytics for insights and intelligence, proactive alerting & troubleshooting and self-service functionality. Point-to-point connections are not suited to such swift change, as each connection needs to be individually upgraded. It is only possible to leverage economies of scale by enlisting the help of a specialised third-party EDI provider.

Many-to-many connections

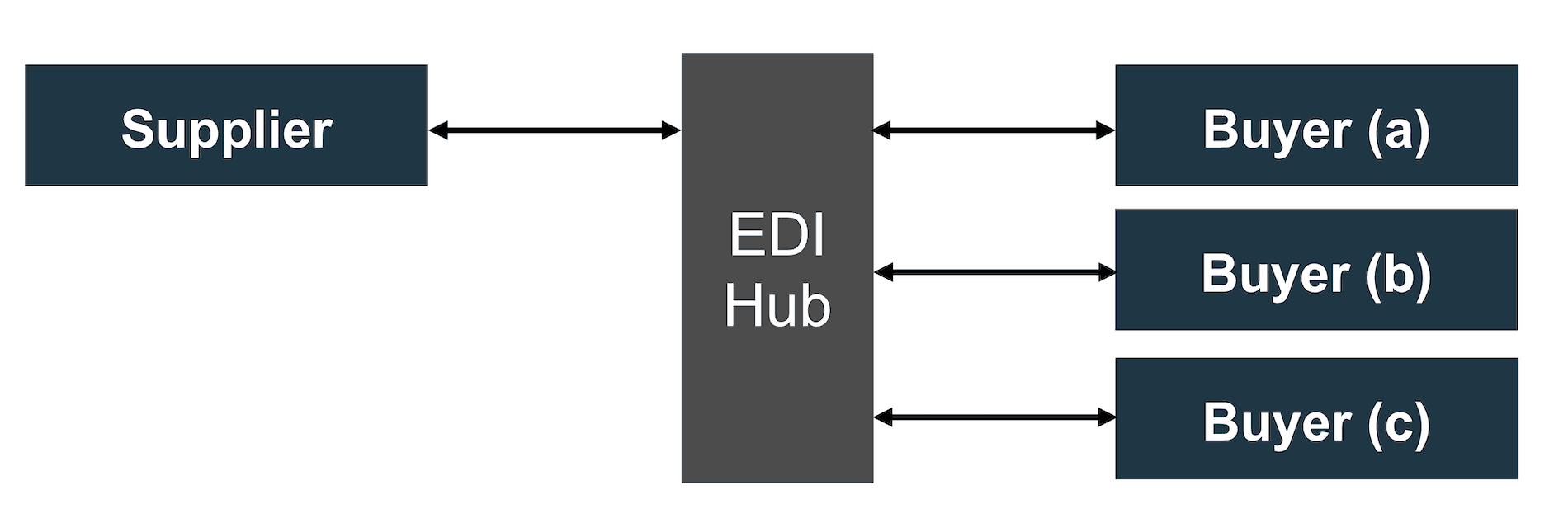

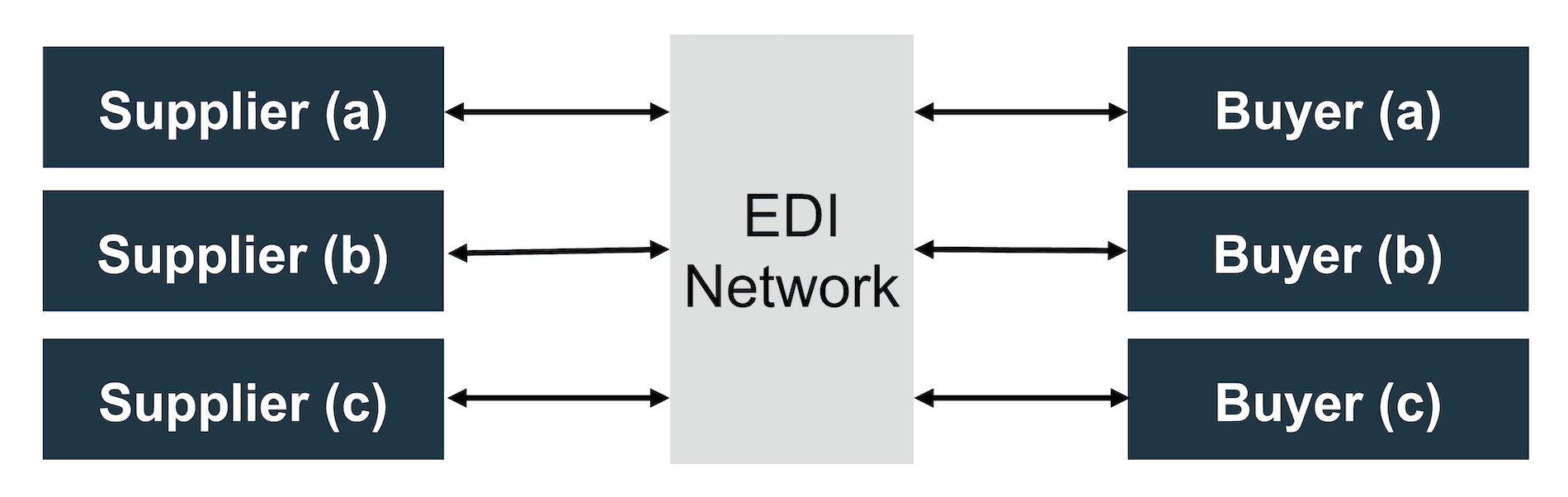

Before the adoption of the cloud or the World Wide Web, large enterprises would avoid the challenges seen in one-to-one relations and share information across private telecommunication networks. This is called a many-to-many (or any-to-any) approach, as any company that is connected to the network can in principle exchange documents with anyone else in that network. Many-to-many relations enable network effects, as each participant in the network can add to or gain value from the network by connecting to it (suppliers and buyers in this case).

You can see how this works in the figure below using the example of supplier-buyer relations.

Many-to-many connections for suppliers and buyers

One-to-many connections

While a many-to-many approach is by far the most efficient design for VANs to use, many providers still use a one-to-many approach. In this type of system, the partner community is ring-fenced and the connections are exclusive to the customer, as shown in the image below:

In a one-to-many scenario, if you presume the company is a supplier and wants to do business with different customers by connecting via EDI, each connection with the “EDI Hub” is independent. This means the connections are not reusable by other suppliers as the instance of the Hub is separate from a shared network (even if hosted on the cloud). This can greatly impact time-to-value of onboarding new partners and making changes, as connections are not operating across a single platform network.

What to look for in a good EDI Value Added Network

If you are looking to use an external EDI VAN provider, be sure to ask the following questions:

Do they operate a many-to-many or one-to-many approach?

If you value flexibility and speed, be sure to opt for a solution that uses a many-to-many approach. You can check this by asking if providers allow for reuse of existing connections in their partner network and how those connections are facilitated across their systems to see if it makes sense to your business. Often traditional vendors have federated legacy systems which can cause further issues or charge extra to be part of their network. Modern B2B IT vendors should not be charging extra for being part of their network.

What value do they add?

While every VAN will be able to connect you with trading partners in the network, some will offer much more than others. For example, some network providers may offer additional services including:

- Self-service for relevant teams to view, access and edit EDI information

- Proactive support, to ensure issues and errors are identified and resolved as fast as possible

- Monitoring, visibility and analytics, so users can track end-to-end performance of messages in real-time

When deciding on a VAN it’s important to think about the additional elements listed above, which are often mission critical to supply chain success. Many EDI vendors and providers overstate their capabilities, which can lead to further issues later on, e.g. delays, message errors, additional costs or even lost sales.

One way to measure a Value Added Network or EDI provider’s ability to execute in a modern hyper-connected environment is to look at the latest innovations or key product releases to determine whether they really are updating their offering over time.

How much in-house work will be required?

If you don’t have in-house EDI expertise, it makes sense to minimise the amount of tasks you handle internally. While there are some businesses who can operate an efficient EDI solution in-house, as we will cover in the next section, the far safer and more efficient approach for most businesses is to outsource EDI tasks to an experienced EDI VAN provider.

For those businesses that wish to outsource EDI tasks completely, a fully managed VAN, such as ecosio, offers the perfect solution. Not only does a fully managed provider deliver messages via the required network, they also handle everything from the initial technical setup and mappings right through to message monitoring and error resolution. Plus you may even be able to integrate the solution into your existing ERP system via API.

To view a detailed comparison of the amount of work done by different EDI providers, download our infographic on this topic.

Five reasons to avoid using in-house EDI converters

1) The need for EDI expertise and internal resources

Undoubtedly the main hurdle stopping businesses from attempting to manage EDI in-house is the complexity of EDI processes. Unfortunately, given the way in which EDI has developed over the decades and the myriad of formats and protocols available to businesses today, managing EDI requires significant technical expertise which is rare among in-house IT professionals. Further, even when a business does have sufficient EDI expertise, they may not have enough resources to cope with system setup and/or ongoing operation. Unless you are willing to invest in new staff members to cope with the additional workload, you risk overloading your IT team and increasing the likelihood of errors as a result.

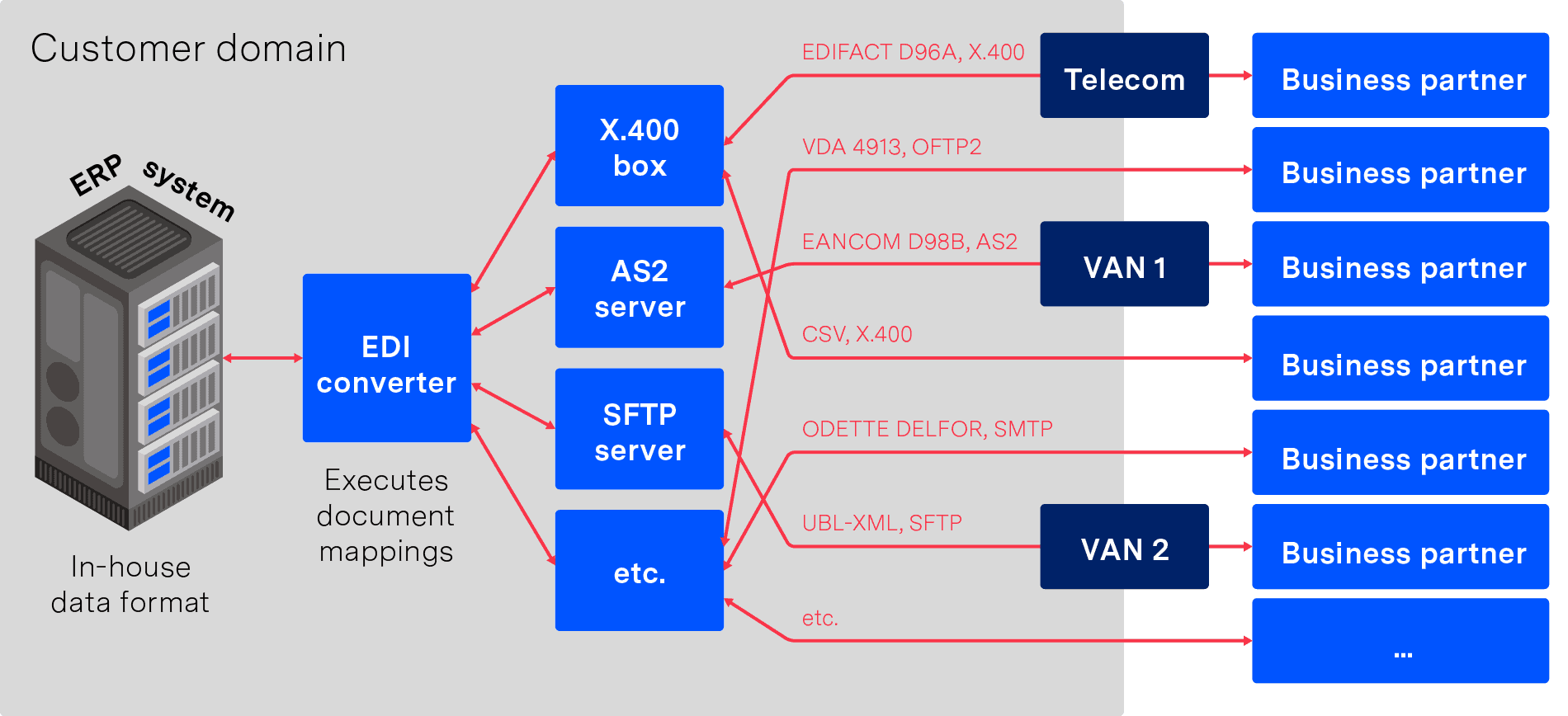

2) Maintenance of various different servers

When handling EDI via an EDI converter it is often necessary to maintain various different servers. These are needed to enable the transmission of certain document formats over different protocols to various VANs and partners. For example (as pictured below) you might easily need to maintain an X.400 mailbox as well as both an AS2 and an SFTP server to be able to reach all your business partners. In such a scenario you also need to monitor and maintain the connections to and from these servers, including any interconnects to different VANs.

Further, as EDI enables the transmission of business-critical documents such as orders and invoices, it is imperative that total system failure is safeguarded against. The only way to do this properly is to maintain multiple redundant servers so that all message exchange and archived messages are backed up. However, as this involves investing even more on hardware etc. than the already significant amount required to maintain a single server, many businesses opt not to provide EDI systems in a redundant manner. In so doing, these businesses risk catastrophic financial consequences should total system failure occur.

3) Monitoring of connections and interconnections with different VANs etc.

There are many problems with having to juggle multiple VAN connections. In short, these issues concern the difficulty of message tracing, maintaining multiple VAN mailboxes and resolving errors (something made particularly hard by the fact there is often no clear point of contact). Unfortunately, these issues are unavoidable for companies that choose to handle EDI internally, as the only future-proof way to simplify messy EDI landscapes is to pass the management of VAN connections to an EDI solution provider such as ecosio.

4) High likelihood of errors occurring

Whereas fully managed VANs will have rigorous and reliable testing, onboarding and verification procedures in place, this is often not the case with in-house arrangements. As in-house teams often have a large and varied workload it is easy for oversights to occur during system setup which are hard to correct further down the line (neglecting to test for every possible iteration of an invoice, for example). Also, the more VANs that are being used, the higher the likelihood of errors occurring.

5) The cost!

Unsurprisingly conducting EDI in-house is not cheap. Not only does purchasing the necessary hardware and software require significant outlay (particularly if multiple servers are required), the time and staff costs are also considerable.

Final thoughts

To take advantage of a hyper-connected world, it’s important to leverage many-to-many networks to drive commerce with your trading partners. It increases speed and agility to ultimately achieve the best outcomes for your business. Although this service has been in place since the 1980’s it’s crucial to consider additional benefits as part of a B2B e-commerce network, e.g. self-service, support, monitoring, analytics and troubleshooting. In the future these will be necessary requirements for any Value Added Network.

As many traditional EDI vendors and solutions overstate their capabilities, it’s important to look at proof of continued innovation and to understand clearly how your proposed supplier’s support model works.

Want to solve your VAN connection headache?

This article includes a snippet from our white paper Everything You Need to Know About VANs. In this paper we explore the different types of VANs, the benefits of doing EDI via API and the practical steps you can take to improve your EDI landscape and minimise VAN costs (among other topics).

Download your copy and find out how you can optimise your processes now!

Alternatively, if you have any questions about VANs or anything else EDI related, feel free to get in touch. We’re always happy to help!

Der Beitrag Value Added Network (VAN) – Key Questions Answered erschien zuerst auf ecosio.

]]>Der Beitrag Electronic Data Interchange (EDI) with 3M erschien zuerst auf ecosio.

]]>Even if you have not heard about 3M in the past, it is quite likely that you stumbled upon one of their products in everyday life. One of their most famous products is, without doubt, the Post It note. In innovation classes, Post It notes are often taken as a famous example for a serendipity innovation. Originally in search for a super-strong adhesive, the chemist at 3M created a low-tack glue which allows for an easy attachment and detachment of the glued item. The rest is history.

Today 3M produces much more than just Post It notes. In order to allow for efficient management of its procurement and distribution processes, 3M makes heavy use of electronic data interchange (EDI). In the rest of the article we outline the most important facts in regard to EDI on the supplier’s side – that is, if your company delivers goods or services to 3M.

EDI with 3M

If you have been requested to start doing EDI with 3M, there are three important aspects to consider: document formats, exchange protocol and the onboarding process with 3M. We will further examine all three aspects in detail.

EDI document formats

On the supplier side 3M typically focuses on the following EDI document types:

- ORDERS (Purchase Order)

- ORDCHG (Purchase Order Change)

- ORDRSP (Purchase Order Response)

- DESADV (Despatch Advice)

- INVOIC (Invoice)

Thereby, they support the following EDI document formats:

- EDIFACT D96A

- ANSI ASC X12 version 4010

The exact format specifications may be retrieved as follows.

- Go to: https://www.3m.com

- Select your preferred Location/Language

- Select menu options > Suppliers > Source to Pay Transactions > Electronic Data Interchange

- Download the required document

Unless your ERP system is able to directly import and export the EDI formats mentioned above (which is unlikely), you have to employ a converter solution. The converter solution translates between the document format of your ERP system and the EDI format of 3M and vice versa. Usually converter solutions come either as an on-premise solution, or are provided by a service provider as a managed solution.

Of particular importance in regard to the document formats is the turnaround of information from 3M to your ERP and back to 3M. To be more precise – several identifiers have to be taken from the ORDERS message, which is received from 3M and must be returned in the documents which are being sent back to 3M (ORDRSP, DESADV and INVOIC). When using EDIFACT, the following turnaround principle applies.

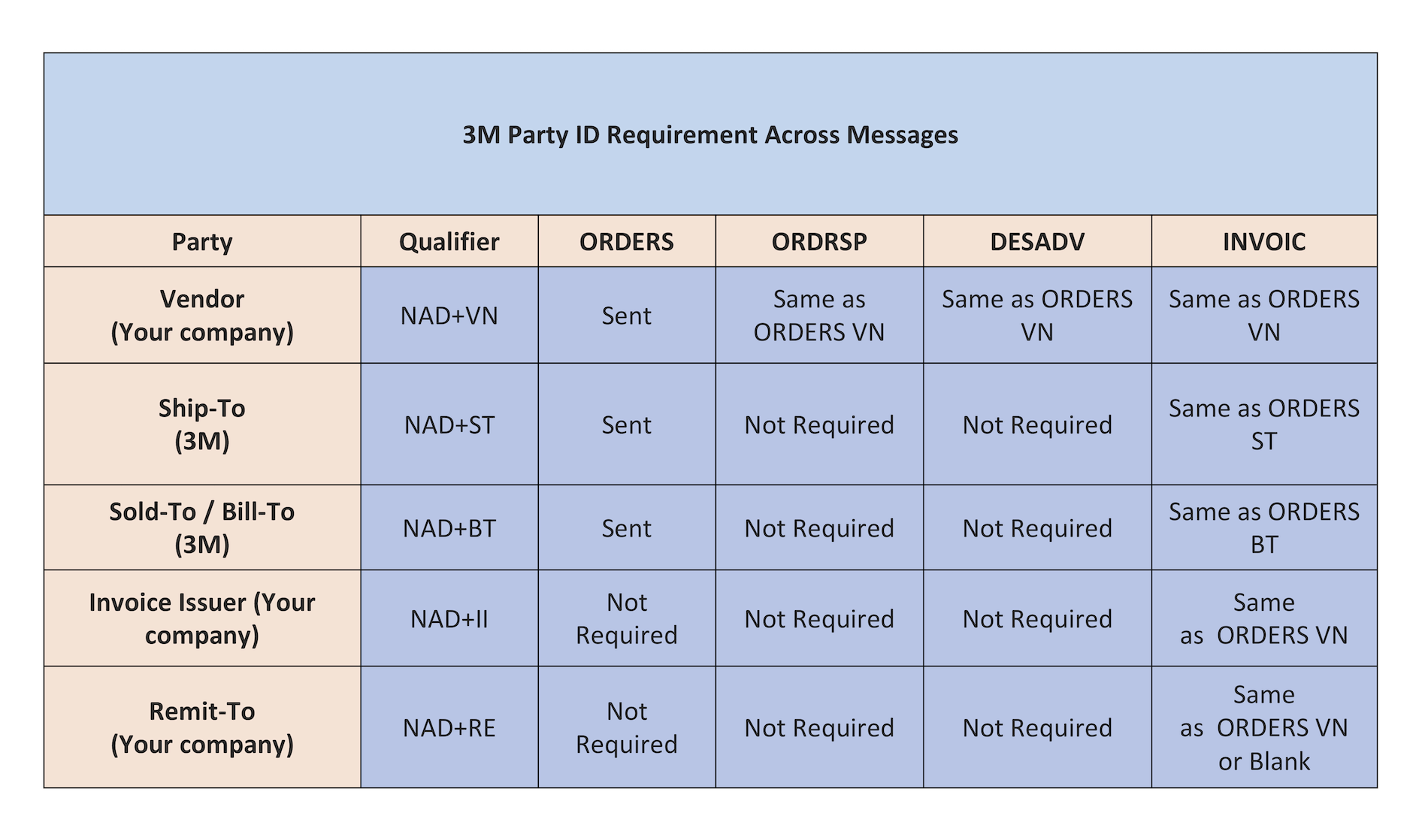

3M Party ID Requirement Across Messages

It is, for instance, essential, that the NAD+VN information from the ORDERS is correctly returned in the ORDRSP, DESADV and INVOIC message. The most complex document type is the INVOIC message. All NAD identifiers from the original ORDERS must be correctly returned in the INVOIC message.

Thus, it is imperative that the correct turnaround process is configured in the ERP system, ensuring that all information from the ORDERS is stored in the ERP and correctly returned when the INVOIC is exported.

When working for instance with an SAP ERP system, the correct configuration of the EDPAR table helps transfer the identifiers from the ORDERS through the ERP and back to the INVOIC document.

EDI exchange protocol

To allow for an exchange of EDI documents with 3M, an exchange channel using an EDI protocol must be set up. An EDI service provider like ecosio can take care of this connection for you and create a connection to 3M’s EDI service provider in order to exchange the required EDI messages. Exact details of the provider will be communicated to you by 3M during the course of the project.

3M along with their EDI service provider will set up two connections: a test connection and a productive connection. The test connection will be used during the onboarding phase to exchange documents with the test system of 3M.

The production connection is then used after the go live.

EDI onboarding process

The EDI team of 3M together with your own EDI service provider will assist you in setting up the EDI process to 3M.

First, master data has to be aligned to avoid disconnects relating to units of measurement and price multipliers. The necessary EDI document mappings should then be set up, after which 3M will provide you with EDI test orders via the test connection. You are then required to send back the necessary order response, despatch advice and invoice documents. Thereby, 3M’s onboarding team will execute various test cases, covering the different aspects of your business relationship to 3M, e.g., different types of deliveries.

After the test phase has been completed successfully, your EDI process will be put into production and your company will start to exchange EDI messages with 3M.

How ecosio can help

Ecosio is experienced in connecting suppliers to 3M and recently connected Mitsubishi Polyester to the conglomerate.

Our unique Integration Hub supports all secure EDI protocols and formats, meaning one connection to ecosio allows message trading with 3M (and other partners) in the correct format and over the correct protocol with minimum effort.

Unlike other providers, ecosio offers an integrated, managed solution which is embedded directly in the user’s ERP system as a native feature. As a result, important processes are built into the existing user interface, producing useful end-to-end message visibility.

Benefits at a glance

- All testing, mapping and routing achieved via a single connection to ecosio’s cloud-based EDI solution (our Integration Hub)

- No internal EDI knowledge needed

- Hassle-free partner onboarding

- Unparalleled end-to-end data visibility thanks to deep ERP integration

Any questions?

If you still have questions, feel free to contact us. We would love to help you!

SAP ERP and SAP S/4HANA are the trademarks or registered trademarks of SAP SE or its affiliates in Germany and in several other countries.

Der Beitrag Electronic Data Interchange (EDI) with 3M erschien zuerst auf ecosio.

]]>