Der Beitrag Supplier Relationship Management – 6 Tips for Retail Businesses erschien zuerst auf ecosio.

]]>For no industry is this truer than for retail. Whilst retail has always been an intensely competitive marketplace, new pressures have been added thanks to the recent shift in customers’ behaviour and expectations, particularly regarding ease of ordering and delivery speed. As well as expecting to receive items within one or two days, consumers increasingly rely on efficient returns as more and more people over-order to try on at home. What’s more, it has never been easier or more impactful for customers to write a negative review if they experience issues regarding an order.

For years retail supply chains were optimised for high-street stores, with online sales considered a subsidiary stream. Consequently, many retail supply chains today suffer from legacy issues related to inefficient logistics processes and poor cross-channel coordination as they struggle to adapt their processes to enable them to meet current demands whilst simultaneously preparing them for the future.

In this article we explore six key things you can do to improve the efficiency of your retail supply chain:

1 – Set out your plan

It may sound simple, but writing down your objectives and how you aim to achieve them is always the most effective starting point. However you seek to tackle the issues you’ve identified, be it through updating your distribution strategy, staff training, outsourcing logistics processes or an increased focus on supplier relationship management (SRM), creating a clear and detailed plan will help to ensure that you are constantly moving towards the outcome you want.

2 – Automate, automate, automate!

Changing logistics and data processes can seem like a daunting task, which is why so many retail supply chain businesses retain outdated systems and struggle to process in an effective manner the numerous different message types (sent via various protocols) received daily from partners. Yet handled correctly, not only is process automation a simple process, it is one which can transform your business.

Key benefits of effective process automation include:

- Time and cost-saving – Arguably the most easily identifiable benefit of automating data exchange, logistics and procurement processes is the time (and resultant money) it can save, from elimination of manual data tasks, to quick and easy data monitoring, in turn enabling easy identification of further areas for process improvement.

- Accuracy and reduction in human error – With a streamlined electronic data interchange (EDI) system in place human errors are all but eliminated, resulting in reliable information exchange and dependable output.

- Collection of useful data – In addition to ensuring the accuracy of the data being exchanged between you and your partners, an efficient B2B integration system can provide useful analytics relating to information such as orders, inventory levels and supplier performance.

In short, as we move towards e-procurement or electronic buying processes, retaining a non-automated system (no matter how attractive that option may seem now) will become increasingly untenable, especially in the fast-moving world of retail. The faster you seek to automate key business processes, the less chance you have of being left behind!

3 – Improve supplier relationships

Healthy supplier relationships form the backbone of a successful retail supply chain. The best relationships are not simply transactional connections, but more like alliances. By enhancing your B2B integration you can boost supplier relationship management through accurate data forecasting, automated deadline reminders and improved workflows, in turn relieving procurement teams and minimising costly errors and oversights.

Help your suppliers to help you!

With a future-proof electronic data interchange (EDI) system in place not only will you and your partners be speaking the same data language, the resulting improvement in supply chain visibility will allow them to see key inventory information, ensuring they are better positioned to fill future orders. Thanks to web-based EDI portals, today even partners who don’t currently have an EDI system can be connected to enable these advantages across your entire network.

4 – Monitor supplier performance

As we’ve already established, good supplier relationship management is key to retail supply chain success. In addition to improving the efficiency of your supplier relationships by streamlining data transfer, implementing an efficient B2B integration system can also provide access to easy-to-digest information regarding supplier performance. With quick access to key performance indicators (KPIs) such as partners’ fill rates and order accuracy, identification of areas for improvement becomes simple. In addition, you may want, if possible, to set targets for your partners to make sure they are aware of what is expected of them and allow both parties to track task progress. Ideally, performance can then be tracked directly through your B2B integration hub via supplier audits and quality management reports.

5 – Maintain data transparency

Unfortunately, no matter how streamlined your supplier relationship management processes are, things will inevitably go wrong from time to time, be it a delayed shipment or a misjudged demand. What’s important when this happens is to catch the issue quickly and identify where things went wrong so as to ensure that it doesn’t happen again. When it comes to data exchange processes, maintaining transparency in the form of full-text searchability across all documents and messages is extremely valuable and allows for issues to be spotted before they can escalate.

6 – Don’t try to do it all yourself!

Just because you know your business better than anyone else, it doesn’t mean you are best placed to implement, manage and monitor day-to-day data processes. The in-house resources required to ensure the success of commerce-critical data exchange can be significant. Plus the difficulty of in-house teams staying on top of day-to-day data routing and mapping tasks alone often means that little to no time is devoted to process improvement and future-proofing key business processes – something that is key in an industry as competitive and dynamic as retail.

By moving to a future-forward, managed EDI service the ongoing hassle of managing logistics and procurement processes is removed. Further, this enhanced B2B integration can also be accompanied by SRM capabilities such as delivery performance and audit management modules, with in-house resources in turn redirected to forward-thinking process improvement.

Find out more

For more information about supplier relationship management and how digitisation of supplier processes could help streamline your supply chain, visit our page “Supplier activation“.

Alternatively, if you have questions about your specific situation please contact us or use our chat – we are happy to help!

Der Beitrag Supplier Relationship Management – 6 Tips for Retail Businesses erschien zuerst auf ecosio.

]]>Der Beitrag The 7 EDI Documents Typically Found in a Trading Partner Cycle erschien zuerst auf ecosio.

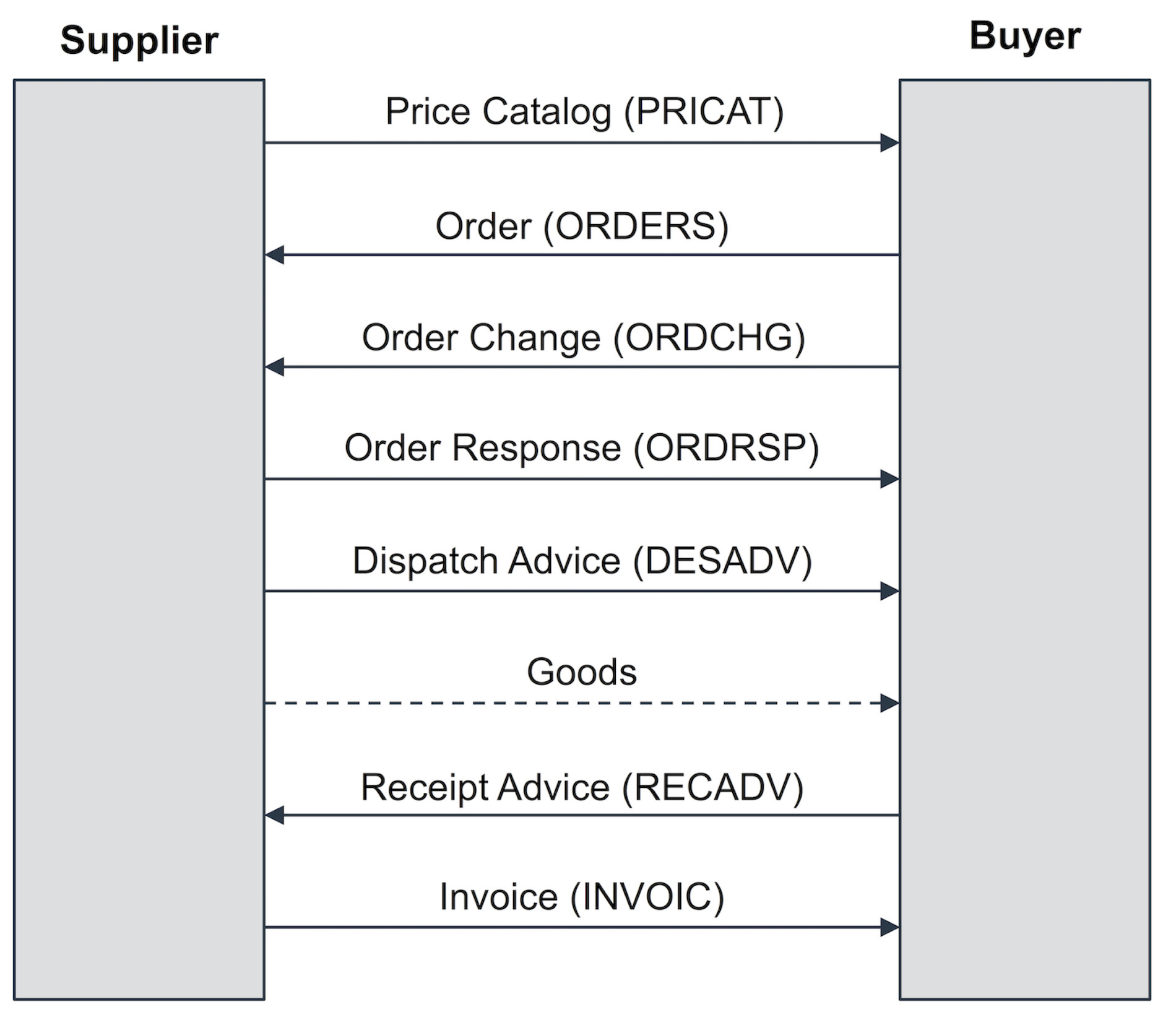

]]>The exchange of business documents is part of a procurement process between suppliers and buyers, whether in retail, automotive or other production industries transacting goods and services on a regular basis. The following figure represents the typical flow of the seven most common EDI documents between a buyer and seller in a trading partner cycle, which I will explain further below.

buyer and seller in a trading partner cycle

Price Catalog (PRICAT)

The first step of the exchange process between trading partners, is the price catalog and is required when the supplier provides the buyer with a current list of its products, product details, as well as price information. This process is commonly referred to as the product master data exchange, however, is not that common in modern trading partner cycles.

Purchase Order (ORDERS)

Once a buyer decides on the parameters of purchase from its supplier, the buyer must send a purchase order in order to receive those good. As such, this document is a necessary EDI transaction used by a customer, e.g. Sainsbury’s or Skanska, to place an order with one of its suppliers, e.g. Nestle or Tata Steel. This will contain the same information included in a traditional paper purchase order (PO), such as specific items and quantities to be produced, pricing and applicable discounts and shipping details. With EDI, the message includes coded information about the buyer, supplier, delivery point, products, etc. This means that unique identifiers such as global location numbers (GLNs) or global trade identification numbers (GTINs) are used for the identification of the involved trading partners and their goods. GLNs and GTINs are mostly found in retail and wholesale – manufacturing and the automotive industry often build on supplier’s or customer’s article numbers for material identification. In regard to partner identification bilaterally agreed IDs (e.g. JLR for Jaguar Landrover) or DUNS numbers are often used.

The benefit of using purchase orders via EDI allows businesses to avoid data entry errors associated with manually entering data into your system. It also reduces time delays and speeds up the process of sending and receiving documents, as well as, eliminating duplicates.

Order Change (ORDCHG)

A buyer may wish to request to change the quantity of goods ordered or the requested delivery date by emitting an order change message, indicating to the supplier a change of the initial purchase order.

Order Response (ORDRSP)

The supplier may acknowledge a received order message or a received order change message using an order response message. The order response can also be used as an Order Confirmation so as to recap and confirm what was in the purchase order. The supplier is essentially telling the customer that the order was received and they will take the job. It closes the loop and confirms the order electronically, without a follow up call or fax. The document can also indicate that the purchase order was accepted or rejected. It can even indicate any changes in pricing or quantity, alert the customer of product availability (in stock or backorder) and provide ship and delivery dates.

An automatic update of confirming an order or response will prevent confusion or mistakes when the invoice is sent later down the line. Time and money is saved by not having to follow up manually and check.

Dispatch Advice (DESADV)

A supplier notifies the buyer of the shipped good the buyer can expect to receive. Using the dispatch advice message, the supplier provides the buyer with information about the shipment including number of pallets, pallet identification numbers such as serial shipping container codes (SSCC), net and gross weight, identification of the transport vehicle such as license plate number of the truck, etc.

The benefit of this is that the buyer may coordinate the arrival and processing of the goods-to-arrive, e.g., in case of cross-docking-scenarios, frozen goods, etc. Furthermore, the buyer may verify the completeness of the shipment by comparing the received goods with the information provided in the previously received dispatch advice message.

Receipt Advice (RECADV)

After the goods have been received by the buyer, the buyer may emit a receipt advice message, confirming the amount of received goods. The amount of confirmed goods in the receipt advice may be different from the amount communicated by the supplier in the dispatch advice. Reasons for such a deviation may for instance be damaged goods the buyer refuses to accept or a wrong number of goods shipped by the supplier.

Invoice (INVOIC)

An outbound EDI document that replaces the traditional paper invoice. This document basically says that your order is complete and has shipped, so now we are billing you. Invoice details typically include goods provided, shipping particulars and payment terms. If your EDI is embedded, the invoice data is usually translated directly out of your accounts receivable module into the EDI document and subsequently into the accounts payable module of the customer.

Questions about the trading partner cycle of document types?

If you’d like more help with gathering your requirements from your supply chain, you can reach out – we’d be happy to help. or check out our chat.

Der Beitrag The 7 EDI Documents Typically Found in a Trading Partner Cycle erschien zuerst auf ecosio.

]]>